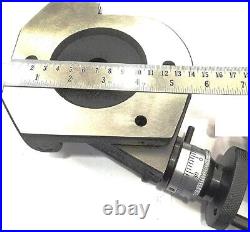

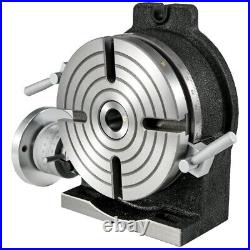

Horizontal Vertical 4 Inch II 100 mm MT2 Center Bore Tilting Rotary Table

Horizontal Vertical 4 Inch II 110 mm – MT2 Center Bore Tilting Rotary Milling Tables. Precision Engineering: Crafted with meticulous attention to detail, our HV4-MT2 Center Bore Rotary Table ensures superior accuracy and performance in your machining operations. Robust Construction: Built with quality materials, this rotary table boasts a sturdy and durable design, providing long-lasting reliability in your workshop. MT2 Center Bore: Features a reliable MT2 center bore, offering secure mounting and precise alignment for your workpieces. Versatile Compatibility: Compatible with a wide range of machining tasks, including milling, drilling, cutting threads, and more, making it a versatile addition to your workshop. Ample Space: With its HV4 size, this rotary table provides ample space for accommodating various workpieces, allowing you to tackle a variety of projects with ease. Easy to Use: Designed for user convenience, this rotary table is easy to set up and operate, ensuring a smooth and efficient workflow in your machining tasks. Professional Grade: Whether you’re a professional machinist or a hobbyist, our HV4-MT2 Center Bore Rotary Table offers professional-grade performance and reliability for all your machining needs. Essential Tool: A must-have tool for any workshop, this rotary table enhances your machining capabilities and helps you achieve precision and accuracy in your projects. Upgrade Your Workshop: Elevate your workshop with the superior performance and versatility of our HV4-MT2 Center Bore Rotary Table, the perfect addition to any machining setup.

8 Precision Horizontal & Vertical Rotary Table ISO9001#TSL200 New

8 Precision Horizontal & Vertical Rotary Table ISO9001#TSL200 – New. 8 PRECISION HORIZONTAL & VERTICAL ROTARY TABLE ISO9001 #TSL200 – NEW. PRECISION ROTARY TABLE /HORIZONTAL&VERTICAL – NEW EXTRA DEEP COOLANT DUAL POSITIVE ACTION LOCKS SATIN CHROME DIALS LOW PROFILE 10 SECONDS VERNIER READING GEAR DRIVE IMMERSED IN IOL OPTIONAL DRIVING PLATES AND TAILSTOCK TABLE SIZE: 8″ 3/4″ table slot CENTER BORE: 3MT. We reserve the right to cancel any order for any reason at any time. We are not responsible for undeliverable addresses. Your feedback very important to us, after you get your package and you are. Satisfied with our service. If you have any problem with your order / any questions please before leave any type of feedback. Thank you for shopping at our store.

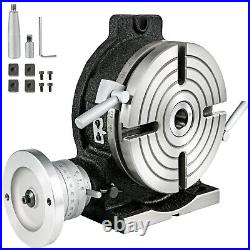

4” inch 100mm Rotary Table Horizontal & Vertical Model Precision- USA

4” inch – 100mm Rotary Table Horizontal & Vertical Model Precision, Rotary, Milling, Indexing machine Table. Very High Quality 4 /100 mm Regular Rotary Table designed for smaller milling machines. Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16 (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. This 4-inch (100mm) Rotary Table offers both horizontal and vertical orientation capabilities, providing versatility for a wide range of machining tasks. Whether you need to perform horizontal milling or vertical indexing operations, this rotary table delivers precision and accuracy in both orientations. Engineered for precision machining, this rotary table ensures accurate indexing and positioning of workpieces. Its finely crafted mechanism enables smooth rotation and precise angular adjustments, allowing for the creation of intricate and high-quality machined components. Crafted from durable materials, this rotary table features a sturdy construction that withstands the rigors of machining environments. Its robust design ensures stability and reliability during operation, providing a solid foundation for machining tasks. Equipped with a smooth rotary action, this rotary table facilitates seamless movement and precise positioning of workpieces. Whether you’re indexing for drilling, milling, or grinding operations, its smooth rotation enhances efficiency and accuracy in machining tasks. Horizontal and Vertical Milling Compatibility. With its horizontal and vertical orientation capabilities, this rotary table is compatible with both horizontal and vertical milling machines. Its universal compatibility allows for seamless integration into various machining setups, expanding the capabilities of your milling equipment. From prototyping and production machining to custom fabrication and repair work, this rotary table is suitable for a wide range of applications. Whether you’re working with metal, wood, or other materials, its versatility and precision make it an indispensable tool for machinists, hobbyists, and professionals alike. Achieve precise indexing and angular positioning with this rotary table. Its accurate graduations and locking mechanism ensure repeatable and consistent results, allowing machinists to achieve the desired angles and dimensions with confidence. Despite its robust capabilities, this rotary table features a compact size that maximizes workspace efficiency. Its compact design makes it suitable for use in workshops with limited space, without compromising on functionality or performance. Easy Setup and Operation. Designed for ease of setup and operation, this rotary table allows machinists to quickly and efficiently configure their machining setups. Its intuitive design and user-friendly features streamline workflow, reducing setup time and increasing productivity in the workshop. Whether you’re a professional machinist or a hobbyist, this rotary table delivers professional-grade results with every use. Its precision engineering and versatile capabilities enable machinists to achieve high-quality machining results that meet the most demanding standards of craftsmanship.

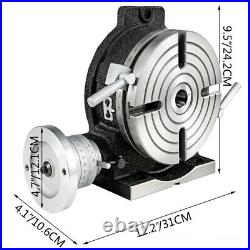

8 Precision Horizontal and Vertical Rotary Table The Ultimate Milling Companion

Universal 8 Precision Horizontal and Vertical Rotary Table: The Ultimate Milling Companion. Exceptional Quality and Versatility. Universal 8 Precision Horizontal and Vertical Rotary Table. A versatile and high-precision tool designed to elevate your milling, drilling, and boring tasks. Crafted from top-grade HT200 casting, this rotary table promises durability, reliability, and outstanding performance in any workshop. The rotary table is constructed from HT200 casting, a material known for its excellent shock absorption, heat resistance, and high strength. This ensures the table’s longevity and consistent performance, even under demanding conditions. Horizontal and Vertical Use. Designed to be used both horizontally and vertically, this rotary table provides exceptional flexibility. Whether you need to perform circle cutting, indexing drilling, or milling, this table can handle it all. Its dual-functionality makes it an indispensable tool for any serious machinist. 360-Degree Graduated Indexing Plate. Minimum Scale: 10 Seconds. Precision is at the heart of this rotary table’s design. The indexing plate is graduated 360 degrees, allowing for exact positioning. The handle offers 4 degrees per revolution, with a minimum scale marked at 10 seconds. This ensures you can execute even the most complex tasks with unparalleled accuracy. Adjusting the table is straightforward. The dial is clearly marked with an accurate scale, allowing you to quickly set it to the desired position. This user-friendly feature saves time and enhances the efficiency of your work processes. Includes Wrench, Positioning Keys, and Mounting Screws. The Universal rotary table comes with a complete set of accessories, including a wrench, two positioning keys, and mounting screws. These accessories facilitate easy installation and ensure you have everything needed to start working immediately. Wide Range of Applications. Ideal for Milling, Drilling, and Boring. This rotary table is not limited to a single type of task. It’s perfect for a variety of applications such as index boring, milling, circle cutting, spot facing, and boring holes. Its practical design meets diverse workshop needs, making it a versatile addition to your toolkit. 105 mm (4.13 inches). 40 mm (1.57 inches). 1 Wrench, 2 Positioning Keys, 2 Mounting Screws, 1 Vertical and Horizontal Rotary Working Table. Why Choose the Universal 8 Precision Rotary Table? Unmatched Quality and Precision. Crafted from durable HT200 casting, this rotary table offers remarkable quality. Its precision engineering ensures exacting standards for all your machining tasks. The ability to use the table both horizontally and vertically expands its usability, allowing you to tackle a wide range of projects with a single tool. With easy-to-read scales and straightforward adjustments, this rotary table is designed to enhance your workflow and reduce setup time. The inclusion of essential accessories means you’re ready to go right out of the box, adding convenience and value. Upgrade your workshop with the. Experience the perfect blend of durability, precision, and versatility in one exceptional tool. Get yours today and take your machining projects to the next level!

Johnson Level & Tool 40-6590 JLX Horizontal/Vertical Tracking Rotary System

Johnson Level & Tool 40-6590 JLX Horizontal/Vertical Tracking Rotary System with GreenBrite Technology. Listing and template services provided by inkFrog.

3 inches 75mm 4 slots Horizontal and Vertical H/V Rotary Table with 65mm 3 Jaws

A great combo of 3/80 mm Rotary table with 65 mm self centering chuck with back plates & Tnuts- A perfect milling combo for smaller mills. 3inches rotary Table: 1. Quality Low Profile Rotary Table diameter 80 mm (3Inches). Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position without chuck: 2-5/8 (66 mm approx) 4. Hand wheel is graduated in divisions of 10 min & can be set to zero. 65mm 3 Jaws Self Centering Chuck: 1. 65 mm 3 Jaws Self Centering Chuck M14 x 1 mounting Thread 2. Back Plate also has M14 x 1 thread Spigot to mount the Chuck on it. Back Plate is drilled in a manner that it can be fitted ONLY to 4 Slot Rotary Table. Suitable T -nuts are also supplied.

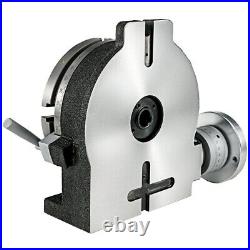

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Table

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Table. Transform your machining capabilities with our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Engineered for precision and versatility, these rotary tables are designed to elevate your machining projects to new heights. Dual functionality: Can be used horizontally or vertically to accommodate a wide range of machining tasks. Generous 4 inch (100 mm) diameter provides ample space for various workpieces. Smooth rotary motion ensures precise positioning and milling operations. Sturdy construction for durability and long-lasting performance. Compatible with both horizontal and vertical milling machines, enhancing flexibility in your workshop. Precision-machined for exceptional accuracy, delivering reliable results with every use. Whether you’re performing intricate machining tasks or tackling larger projects, our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables deliver the precision and versatility you need for outstanding results. Upgrade your machining capabilities with the precision and versatility of our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Elevate your workshop today!

4 Jaws 80mm Independent Dog chuck with Back Plate And T nuts for Rotary Table

80 mm 4 Jaws Independent Dog chuck with Back Plate And T nuts for Rotary Table. 80 mm 4 Jaws Independent Dog Chuck. Quality 80 mm Diameter 4 Jaw Independent Chuck. Body is made of Graded Casting. Jaws are of Alloy Tool Steel -Hardened and Ground. Supplied with a Tool Steel Back Plate having same recess as that of the chuck. The plate is threaded drilled in a manner that the chuck can be screwed to the Back Plate. The Back plate has been counter drilled to fit to our 3″/ 80mm & 4″/ 100 mm Rotary tables. The other side of the Back plate has a small spigot to fit /adjust into the center of the Rotary table for better accuracy and Fitting. Supplied with Fixing T nuts Bolts. PROUDLY MADE IN INDIA. ? RSTOOLS comprises of a dedicated and skilled team of engineers with an aim of providing you tools of highest indian industrial standards. Situated at the industrial hub of. We specialize in providing complete tooling solutions. Our Motto : Right Quality. We ensure the product reaches you at the earliest. We are looking forward to your positive reviews and to build a long term relationship. 80 mm 4 jaws independent dog chuck machine. 80 mm 4 jaws independent dog chuck motor. 80 mm 4 jaws independent dog chuck me. 80 mm 4 jaws independent dog chuck mini. 80 mm 4 jaws independent dog chucker. 80 mm 4 jaws independent dog chucks. 80 mm 4 jaws independent dog chuck chucks. 80 mm 4 jaws independent dog chuck yeager. 80 mm 4 jaws independent dog chuck young. 80 mm 4 jaws independent dog chuck removal. 80 mm 4 jaws independent dog chuck review. 80 mm 4 jaws independent dog chuck repair. 80 mm 4 jaws independent dog chuck rod. 80 mm 4 jaws independent dog chuck raw. 80 mm 4 jaws independent dog chuck norris. 80 mm 4 jaws independent dog chuck weight. 80 mm 4 jaws independent dog chuck wagon. 80 mm 4 jaws independent dog chuck well. 80 mm 4 jaws independent dog chuck it. 80 mm 4 jaws independent dog chuck dog. 80 mm 4 jaws independent dog chuck drill. 80 mm 4 jaws independent dog chuck dhillon. 80 mm 4 jaws independent dog chuck drill machine. 80 mm 4 jaws independent dog chuck diapers. 80 mm 4 jaws independent dog chuck guide. 80 mm 4 jaws independent dog chuck guard. 80 mm 4 jaws independent dog chuck gun. 80 mm 4 jaws independent dog chuck grip. 80 mm 4 jaws independent dog chuck back. 80 mm 4 jaws independent dog chuck bolt. 80 mm 4 jaws independent dog chuck bit. 80 mm 4 jaws independent dog chuck bite. 80 mm 4 jaws independent dog chuck backpack. 80 mm 4 jaws independent dog chuck zig zag. 80 mm 4 jaws independent dog chuck zero. 80 mm 4 jaws independent dog chuck zito. 80 mm 4 jaws independent dog chuck video. 80 mm 4 jaws independent dog chuck videos youtube. 80 mm 4 jaws independent dog chuck quality. 80 mm 4 jaws independent dog chuck quora. 80 mm 4 jaws independent dog chuck question answer. 80 mm 4 jaws independent dog chuck and blade. 80 mm 4 jaws independent dog chuck and cheese. 80 mm 4 jaws independent dog chuck amazon. 80 mm 4 jaws independent dog chuck and blair. 80 mm 4 jaws independent dog chuck joint. 80 mm 4 jaws independent dog chuck jaw. 80 mm 4 jaws independent dog chuck jointer. 80 mm 4 jaws independent dog chuck olx. 80 mm 4 jaws independent dog chuck off. 80 mm 4 jaws independent dog chuck on amazon. 80 mm 4 jaws independent dog chuck e cheese. 80 mm 4 jaws independent dog chuck exercise. 80 mm 4 jaws independent dog chuck eye. 80 mm 4 jaws independent dog chuck price. 80 mm 4 jaws independent dog chuck price in india. Independent dog chuck norris. Independent dog chuck e cheese. Independent dog chuck eye. Independent dog chuck eye problems. Independent dog chuck and cheese. Independent dog chuck meme. Independent dog chuck mangione. Independent dog chuck mangel. Independent dog chuck dog. Independent dog chuck dog food. Independent dog chuck dog breed. Independent dog chuck doge. Independent dog chuck berry. Independent dog chuck bass. Independent dog chuck bite. Independent dog chuck hughes. Independent dog chuck holder. Independent dog chuck head. Independent dog chuck chuck. Independent dog chuck chucky. Independent dog chuck video. Independent dog chuck videos youtube. Independent dog chuck for sale. Independent dog chuck feeder. Independent dog chuck for sale in india. Independent dog chuck norris quotes. Independent dog chuck norris meme. Independent dog chuck norris gif. Independent dog chuck uk. Independent dog chuck up. Independent dog chuck roast. Independent dog chuck roll. Independent dog chuck rdr2. Independent dog chuck removal. Independent dog chuck rawlings. Independent dog chuck quotes. Independent dog chuck quora. Independent dog chuck question answer. Independent dog chuck queen. Independent dog chuck young. Independent dog chuck yeager. Independent dog chuck youtube. Independent dog chuck taylor. Independent dog chuck toy. Independent dog chuck close. Independent dog chuck crompton. Independent dog chuck joint. Independent dog chuck jaw. Independent dog chuck jar. Independent dog chuck jonas. Independent dog chuck olx. Independent dog chuck olx haryana. Independent dog chuck osborne. Independent dog chuck oswald. Independent dog chuck image. Independent dog chuck in chandigarh. Independent dog chuck it. Independent dog chuck in kurukshetra. Independent dog chuck in india. Independent dog chuck gif. Independent dog chuck groom. Independent dog chuck grip. Independent dog chuck groomer. Independent dog chuck wagon. Independent dog chuck wepner. Independent dog chuck well. Independent dog chuck works. Independent dog chuck palahniuk. Independent dog chuck price. Independent dog chuck pack. Independent dog chuck price in india. Independent dog chuck chucks. Independent dog chuck chucks for sale. Independent dog chuck lorre. Independent dog chuck liddell. Independent dog chuck lead. Independent dog chuck lock. Independent dog chuck low. Independent dog chuck xd. Independent dog chuck xy. Independent dog chuck xenia. Independent dog chuck xenon. Independent dog chuck zimmer. Independent dog chuck zapper. Independent dog chuck zappa. Independent dog chuck zhou. Independent dog chuck zito.