milling

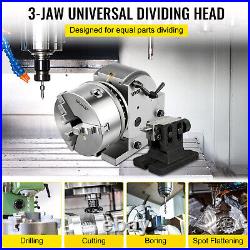

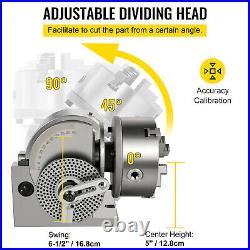

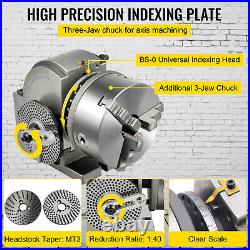

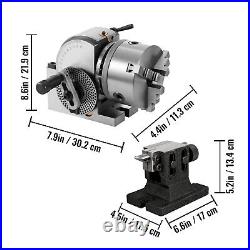

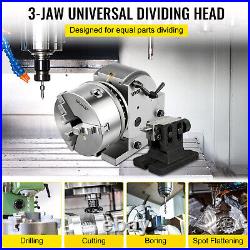

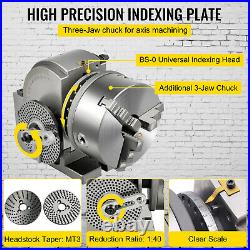

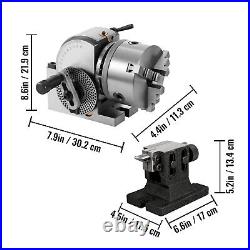

Indexing Dividing Head BS-1 6 3 Jaw Chuck & Tailstock for CNC Milling Machine

6 / 160 mm Dividing Head for Milling Machine. MT3 Headstock Taper & Complete Set & Simple Operation. Semi-Universal Dividing Head is a simple Index Center and can be used for direct and indirect dividing. Complete the gear, face, flute processing, and no need accessories, the same construction as universal type. With rotary indexer, the 24 quick-dividing holes can complete BS-2A 2,3,4,6,8,12,24 division indexing. Attache 3 dividing plates and the dividing head indirect dividing in any division indexing 2-50.51-380. Rich Dividing Head Set. Tough Equipment & Tools, Pay Less. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Vertical & horizontal milling machine with headstock chuck for the lathe. Swing: 6-1/2″ / 168 mm, Center Height: 5″ / 128 mm. Our universal dividing head features ruggedly constructed hardened and ground worm gear. The reduction ratio is 1:40. Designed with a rotary table and indexing chuck for convenient operation, the 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. The ball-bearing of this indexing head is of high precision and smooth turning. An extra dead center is provided for rapid use. Our rotary indexer comes with 3 dividing plates of different sizes. The tool has easy indexing of divisions from 2 to 50, with most numbers up to 380. The rotary indexer is ideal for various uses in milling, grinding, and drilling work. Chuck Diameter: 6 / 16 cm. Spindle Speed: 2500 RPM. Swing: 6-1/2 / 16.8 cm. Center Height: 5 / 12.8 cm. Reduction Ratio: 1:40. Net Weight: 77 lbs / 35 kg. Headstock Dimensions: 4.4″ x 7.9″ x 11.8 / 11.3 x 30.2 x 21.9 cm. Tailstock Dimensions: 4.5″ x 6.6″ x 5.2 / 11.5 x 17 x 13.4 cm. 1 x 6 Dividing Head. 2 x Dividing Plates. 3 x 6 Chuck Jaws. 1 x Dead Center. 1 x Set of Related Accessories. Adjustable Angle: The semi-universal dividing head features a 6 3-jaw chuck, Spindle Speed: 2500 RPM. The headstock is adjustable from the horizontal position to 90 degrees upward. Free 3 more jaws for 6 chuck. Solid Construction: This indexing head is made of HT 200 to be a long life. A rigid frame provides high accuracy with little backlash for a smooth rotation. Precise & Accurate: Dividing head milling machine with laser engraving scales. The 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. One circle for 360 degrees, one scale stands for 1 degree. MT3 Tailstock Adjustable: Huge live center for heavy-duty workpieces. Ball-bearing precision; turns smoothly. The model of the tailstock is MT3. One extra dead center is included. Rich Dividing Head Set: 3 dividing head index plates are attached along with the dividing head for indirect dividing in any division indexing 2-50, 51-380 except prime numbers and specific other numbers. People Who Bought This Item Also Bought. VEVOR BS-0 Semi 5 Indexing Dividing Head 3-Jaw Chuck Tailstock For CNC Milling. VEVOR Compound Milling Machine Work Table 2 Axis Cross Slide Bench Drill Vise. VEVOR 8 Precision Horizontal and Vertical Rotary Table. Tilting Table 5 x 7inch for Milling Machines Swivel Angle Plate Adjustable Plate. VEVOR Tilting Milling Table Tilting Angle Milling Machine Adjustable Plate. VEVOR Rotary Table XY Axis Rotary Table 8 3-Slot for Milling Drilling. VEVOR 6 Rotary Table Horizontal Vertical Dividing Plates for Milling Machine. VEVOR Square Air Cooled Spindle Motor 2.2KW CNC Spindle Motor 220V ER20 Collet. VEVOR Milling Drilling Machine Worktable Cross Slide Table 4″ X 7.3″ Bench Table. VEVOR 2.2KW Air Cooled Spindle Motor for CNC Router Milling Engraving 4 Bearings. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. Please be aware that. Please DO NOT fill in the PO Box address. California Warehouse: City of Industry, CA. New York State Warehouse: Perth Amboy, NJ. Georgia Warehouse: Austell, GA. North Carolina Warehouse: Grove NC. Oregon Warehouse: AIRPORT WAY Portland, OR. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. 4 / 100 mm. 6 / 160 mm. 0.28 / 7 mm. 0.83 / 21 mm. 6.5 / 168 mm. CA & TX & NJ & GA & NC &OR WAREHOUSE. All emails will be responded to within 12-24 hours.

Milling Indexing 4 Inches / 100 mm Rotary Table Horizontal and Vertical Both wi

Milling Indexing 4 Inches / 100 mm Rotary Table Horizontal and Vertical Both with M6 Clamp Kit & 65 mm 3 Jaws Self Centring Chuck. Track Page Views With.

Rotary Table 4 Inches/100 mm Horizontal Vertical For Milling Quality

Rotary table 4 100mm Horizontal Vertical Model Milling Machine 4 Slots. The Metal: High quality 18 gauge mild iron steel with brass accents. THIS SMALL ROTARY TABLE, WITH A DIAMETER OF 100 MM, CAN BE USED FOR A VARIETY OF MILLING, DRILLING AND CARVING OPERATIONS IN THE HOUSEHOLD ENGINEER’S WORKSHOP. THERE ARE FOUR T-SLOTS TO FIX THE WORK, MACHINED FACES AT RIGHT ANGLES FOR HORIZONTAL AND VERTICAL ASSEMBLY AND 7MM SLOTS TO FIX TO THE MACHINE TABLE. THE INDEXING HANDLE, WHICH ROTATES ONCE FOR EVERY TEN DEGREES OF TABLE ROTATION, IS SUBDIVIDED INTO DEGREES AND QUARTER DEGREES. THE HEIGHT OF THE CENTER WHEN MOUNTED VERTICALLY IS 40 MM. SUPPLIED WITH WORK HOLDING KIT. VERTICAL AND HORIZONTAL MOUNTING T-SLOTS TO FIX THE WORK WHEEL MARKED IN DEGREES AND QUARTER DEGREES. A precision work positioning device used in metalworking, allowing the operator to drill or cut work at exact intervals around a fixed axis. Rotating tables They are most commonly mounted “flat”, with the table rotating about a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternative configuration is to mount the rotary table on its end (or mount it “flat” on a 90° angle plate), so that it rotates about a horizontal axis. A tailstock can also be used in this configuration, thus clamping the workpiece “between centers”. Horizontal/vertical rotary tables are extremely useful accessories for a milling machine. Simple to operate, they allow easy work management and have many varied applications including. Milling curved profiles and angled faces relative to a center line. Drilling or milling in polar coordinates and, when mounted vertically with a tailstock, can be used to machine shafts or spindles. The versatile units can also be used on drilling, boring or slotting machines, allowing for an even greater range of operations. Machining: To set the initial position of the workpiece, simply loosen the zero collar locking handle and rotate the zero collar counterclockwise for about half a turn. The worm is now disconnected from the worm wheel drive, the table can rotate freely independently of the crank and the workpiece can now be precisely aligned. To reengage, simply turn the zero collar clockwise and retighten the locking handle. For machining key flat surfaces on a bolt. For drilling equidistant holes in a circular flange. To cut a round piece with a protruding tang. To create large diameter holes, by milling in a circular tool path, on small routers that do not have the power to drive large twist drills (>0.500/>13 mm). To the mill propellers. To cut complex curves (with proper settings). To cut straight lines at any angle. The holiday season is the busiest shopping period of the year, don’t worry! Our catalog covers all festivals including Thanksgiving, Black Friday, Cyber Monday and Christmas. Please visit our store and get a gift.

Rotary Table 4 Inches/100 mm Horizontal Vertical Milling

Rotary table 4 100mm Horizontal Vertical Model Milling Machine 4 Slots. The Metal: High quality 18 gauge mild iron steel with brass accents. THIS SMALL ROTARY TABLE, WITH A DIAMETER OF 100 MM, CAN BE USED FOR A VARIETY OF MILLING, DRILLING AND CARVING OPERATIONS IN THE HOUSEHOLD ENGINEER’S WORKSHOP. THERE ARE FOUR T-SLOTS TO FIX THE WORK, MACHINED FACES AT RIGHT ANGLES FOR HORIZONTAL AND VERTICAL ASSEMBLY AND 7MM SLOTS TO FIX TO THE MACHINE TABLE. THE INDEXING HANDLE, WHICH ROTATES ONCE FOR EVERY TEN DEGREES OF TABLE ROTATION, IS SUBDIVIDED INTO DEGREES AND QUARTER DEGREES. THE HEIGHT OF THE CENTER WHEN MOUNTED VERTICALLY IS 40 MM. SUPPLIED WITH WORK HOLDING KIT. VERTICAL AND HORIZONTAL MOUNTING T-SLOTS TO FIX THE WORK WHEEL MARKED IN DEGREES AND QUARTER DEGREES. A precision work positioning device used in metalworking, allowing the operator to drill or cut work at exact intervals around a fixed axis. Rotating tables They are most commonly mounted “flat”, with the table rotating about a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternative configuration is to mount the rotary table on its end (or mount it “flat” on a 90° angle plate), so that it rotates about a horizontal axis. A tailstock can also be used in this configuration, thus clamping the workpiece “between centers”. Horizontal/vertical rotary tables are extremely useful accessories for a milling machine. Simple to operate, they allow easy work management and have many varied applications including. Milling curved profiles and angled faces relative to a center line. Drilling or milling in polar coordinates and, when mounted vertically with a tailstock, can be used to machine shafts or spindles. The versatile units can also be used on drilling, boring or slotting machines, allowing for an even greater range of operations. Machining: To set the initial position of the workpiece, simply loosen the zero collar locking handle and rotate the zero collar counterclockwise for about half a turn. The worm is now disconnected from the worm wheel drive, the table can rotate freely independently of the crank and the workpiece can now be precisely aligned. To reengage, simply turn the zero collar clockwise and retighten the locking handle. For machining key flat surfaces on a bolt. For drilling equidistant holes in a circular flange. To cut a round piece with a protruding tang. To create large diameter holes, by milling in a circular tool path, on small routers that do not have the power to drive large twist drills (>0.500/>13 mm). To the mill propellers. To cut complex curves (with proper settings). To cut straight lines at any angle. SIZES AND VARIATIONS: (A) 4/100mm Horizontal Vertical 4 Slot Rotary Table. Chuck diameter 4? (100 mm). Vertical center height 2-1/16? Approx. The steering wheel can be set to zero. Handwheel graduated in 10 min divisions. Cali scolded in 5 minute increments around the edge. It can be used both horizontally and vertically. We ensure that the product reaches you as soon as possible. We are not responsible for them. The holiday season is the busiest shopping period of the year, don’t worry! Our catalog covers all festivals including Thanksgiving, Black Friday, Cyber Monday and Christmas. Please visit our store and get a gift.

4 Inch Rotary Table High Precision Horizontal & Vertical 4 Milling Slots

4 Rotary Table 100mm Horizontal Vertical With 4 Slots For Milling. Can be used in both horizontal & vertical position. Table graduated in 360 Degrees. The scale calibrated in 5 degree increment. Hand Wheel calibrated to 10 degree per revolution with 1/4 degree increment graduations. Please be aware that some countries may have local import regulations which restrict certain products from being imported. Track Page Views With.

Rotary Table 4 Inch/100 mm Horizontal Vertical For Milling Quality

Rotary table 4 100mm Vertical horizontal model 4-slot milling machine. The Metal: High quality 18 gauge soft iron steel with brass accents. THIS NEAT SMALL ROTARY TABLE, WITH A DIAMETER OF 100MM, CAN BE USED FOR A VARIETY OF MILLING, DRILLING AND MARKING OPERATIONS IN THE HOME ENGINEERING WORKSHOP. THERE ARE FOUR T-SLOTS FOR ATTACHING THE WORK, RIGHT-ANGLE MACHINED FACES FOR HORIZONTAL AND VERTICAL MOUNTING AND 7MM SLOTS FOR ATTACHING TO THE MACHINE TABLE. THE INDEXING HANDLE, WHICH ROTATES ONCE EVERY TEN DEGREES OF ROTATION OF THE TABLE, IS SUBDIVIDED INTO DEGREES AND QUARTER DEGREES. THE CENTER HEIGHT WHEN MOUNTED VERTICALLY IS 40MM. SUPPLIED WITH THE WORK TIGHTENING KIT. VERTICAL AND HORIZONTAL MOUNTING T-SLOTS FOR SAFE WORK WHEEL MARKED IN DEGREES AND QUARTER DEGREES. A precision work positioning device used in metalworking, allowing the operator to drill or cut workpieces at exact intervals around a fixed axis. Rotary tables are most often mounted “flat”, with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternative configuration is to mount the rotary table on its end (or mount it “flat” on a 90° angle plate), so that it rotates around a horizontal axis. In this configuration, a tailstock can also be used, thus keeping the part “between centers”. Horizontal/vertical rotary tables are extremely useful accessories for a milling machine. Milling of curved profiles and inclined faces relative to a center line. Drilling or milling at polar coordinates and, when mounted vertically with a tailstock, can be used to machine shafts or spindles. The versatile units can also be used on drilling, reaming or mortising machines allowing an even wider range of operations. Machining – To establish the initial position of the workpiece, simply loosen the zero collar locking handle and turn the zero collar counterclockwise for approximately half a turn. The worm is now disconnected from the worm drive wheel, the table is free to rotate independently of the crank and the workpiece can now be accurately aligned. To re-engage, simply turn the zero collar clockwise and tighten the locking handle. The rotary table uses. To machine flats on a bolt. For drilling equidistant holes on a circular flange. Cut a round piece with a protruding tang. To create large diameter holes, by milling in a circular toolpath, on small milling machines that do not have the power to drive large twist drills (>0.500/>13mm). For cutting complex curves (with proper setup). For cutting straight lines at any angle. The holiday season is the busiest shopping time of the year, don’t worry!!! Our catalog covers all festivals including Thanksgiving, Black Friday, Cyber Monday, Christmas. Please visit our store and treat yourself.

VEVOR Indexing Dividing Head 6 3 Jaw Chuck & Tailstock for CNC Milling Machine

6 / 160 mm Dividing Head for Milling Machine. MT3 Headstock Taper & Complete Set & Simple Operation. Semi-Universal Dividing Head is a simple Index Center and can be used for direct and indirect dividing. Complete the gear, face, flute processing, and no need accessories, the same construction as universal type. With rotary indexer, the 24 quick-dividing holes can complete BS-2A 2,3,4,6,8,12,24 division indexing. Attache 3 dividing plates and the dividing head indirect dividing in any division indexing 2-50.51-380. Rich Dividing Head Set. Tough Equipment & Tools, Pay Less. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Vertical & horizontal milling machine with headstock chuck for the lathe. Swing: 6-1/2″ / 168 mm, Center Height: 5″ / 128 mm. Our universal dividing head features ruggedly constructed hardened and ground worm gear. The reduction ratio is 1:40. Designed with a rotary table and indexing chuck for convenient operation, the 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. The ball-bearing of this indexing head is of high precision and smooth turning. An extra dead center is provided for rapid use. Our rotary indexer comes with 3 dividing plates of different sizes. The tool has easy indexing of divisions from 2 to 50, with most numbers up to 380. The rotary indexer is ideal for various uses in milling, grinding, and drilling work. Chuck Diameter: 6 / 16 cm. Spindle Speed: 2500 RPM. Swing: 6-1/2 / 16.8 cm. Center Height: 5 / 12.8 cm. Reduction Ratio: 1:40. Net Weight: 77 lbs / 35 kg. Headstock Dimensions: 4.4″ x 7.9″ x 11.8 / 11.3 x 30.2 x 21.9 cm. Tailstock Dimensions: 4.5″ x 6.6″ x 5.2 / 11.5 x 17 x 13.4 cm. 1 x 6 Dividing Head. 2 x Dividing Plates. 3 x 6 Chuck Jaws. 1 x Dead Center. 1 x Set of Related Accessories. Adjustable Angle: The semi-universal dividing head features a 6 3-jaw chuck, Spindle Speed: 2500 RPM. The headstock is adjustable from the horizontal position to 90 degrees upward. Free 3 more jaws for 6 chuck. Solid Construction: This indexing head is made of HT 200 to be a long life. A rigid frame provides high accuracy with little backlash for a smooth rotation. Precise & Accurate: Dividing head milling machine with laser engraving scales. The 24 quick-dividing holes can complete 2, 3, 4, 6, 8, 12, 24 division indexing. One circle for 360 degrees, one scale stands for 1 degree. MT3 Tailstock Adjustable: Huge live center for heavy-duty workpieces. Ball-bearing precision; turns smoothly. The model of the tailstock is MT3. One extra dead center is included. Rich Dividing Head Set: 3 dividing head index plates are attached along with the dividing head for indirect dividing in any division indexing 2-50, 51-380 except prime numbers and specific other numbers. People Who Bought This Item Also Bought. VEVOR BS-0 Semi 5 Indexing Dividing Head 3-Jaw Chuck Tailstock For CNC Milling. VEVOR Compound Milling Machine Work Table 2 Axis Cross Slide Bench Drill Vise. VEVOR 8 Precision Horizontal and Vertical Rotary Table. Tilting Table 5 x 7inch for Milling Machines Swivel Angle Plate Adjustable Plate. VEVOR Tilting Milling Table Tilting Angle Milling Machine Adjustable Plate. VEVOR Rotary Table XY Axis Rotary Table 8 3-Slot for Milling Drilling. VEVOR 6 Rotary Table Horizontal Vertical Dividing Plates for Milling Machine. VEVOR Square Air Cooled Spindle Motor 2.2KW CNC Spindle Motor 220V ER20 Collet. VEVOR Milling Drilling Machine Worktable Cross Slide Table 4″ X 7.3″ Bench Table. VEVOR 2.2KW Air Cooled Spindle Motor for CNC Router Milling Engraving 4 Bearings. We believe that it is our vision and mission to provide innovative products with best service and competitive price to satisfy you. Our goal is to make sure that you can find exactly what you are looking for and make it easy for you to place your orders. Please be aware that. Please DO NOT fill in the PO Box address. California Warehouse: City of Industry, CA. New York State Warehouse: Perth Amboy, NJ. Georgia Warehouse: Austell, GA. North Carolina Warehouse: Grove NC. Oregon Warehouse: AIRPORT WAY Portland, OR. If you need to return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Please make sure that item has NO man-made sabotage. Used items will not be accepted for return. All emails will be responded to within. Special circumstances will be listed clearly in the listing. Please do check everything carefully after you received the parcel, any the damage except DOA (Dead-On-Arrival) would not be covered if it’s your fault. 4 / 100 mm. 6 / 160 mm. 0.28 / 7 mm. 0.83 / 21 mm. 6.5 / 168 mm. CA & TX & NJ & GA & NC &OR WAREHOUSE. All emails will be responded to within 12-24 hours.

Diameter 200mm Milling Machine Horizontal Vertical Rotary Table High Precision

HV8 diameter 200mm vertical and horizontal dual purpose milling machine horizontal vertical rotary table high precision. HV series horizontal-vertical indexing plate (vertical-horizontal rotary table) is one of the main accessories of the milling machine, which can be used for indexing drilling or milling, circumferential cutting, boring, countersinking and other work on the milling machine. The worktable has a 360° scale line, a scale ring with a scale value of 1′ and a vernier ring with a minimum differentiation value of 10. The rotary table has a braking and indexing worm shedding mechanism. When the HV series vertical and horizontal turntable is in the vertical position, it can be used in conjunction with the tailstock (special order) to perform circular indexing drilling and milling of more complex workpieces. Made of high-strength FC30 cast iron. Suitable for milling machines or other special machines for cutting and cutting. The new spindle locking system, compared with the traditional bilateral platen type, has stronger locking and more stable cutting. It can be rotated 360 degrees, the handle is rotated 4 degrees, and the minimum scale is drawn for 10 seconds. Can be used in horizontal and vertical directions. Additional special accessories can be made: honeycomb plate and tailstock. Deceleration ratio 1:90.

Vertical & Horizontal Milling Machine Rotary Table 360° for Indexing Drilling

Worktable with scale: 360 °. The vertical & horizontal rotary table, one of the main accessories of the milling machine, is a precision work positioning device. Or, mounted the rotary table on its end (or mount it “flat” on a 90° angle plate) so that it rotates about a horizontal axis.