table

6 in Precision Rotary Table Horizontal Vertical & Index Plate Set Diving Plate

Graduated 360 degree around its circumference and driven by precision gear with 1:90 reduction ratio. One turn by handle moves table 4 degrees. Gear Drive Immersed in Iol. 10 Seconds Vernier Reading. Dual Positive Action Locks. Manufactured from High grade seasons casting and powder coated wrinkled finish for smooth looks. Gear Ratio 90:1. T Slot 16 mm. Dividing Plate Set. Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. Comes complete with Necessary Screws, Washers & handles.

Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machi

VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3.

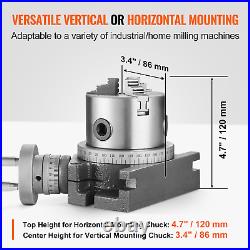

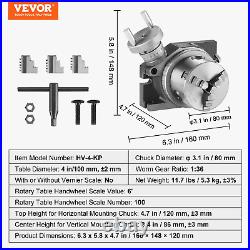

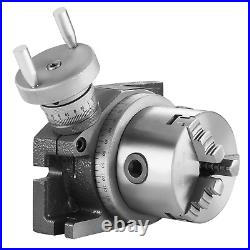

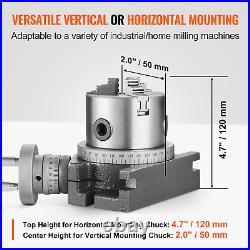

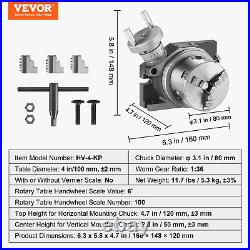

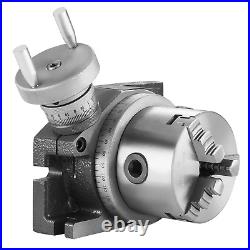

Precision 4” Rotary Table for Milling Machines Horizontal Vertical Model with

The VEVOR Precision 4” Rotary Table for Milling Machines is an indispensable tool for milling engineering and indexing operations. Engineered for precision and durability, this horizontal and vertical model comes equipped with a 3.1” 3-Jaw Chuck and M10 T-Bolts Nuts, ensuring seamless integration with your milling machine setup. High Precision Engineering: Achieve outstanding accuracy with the rotary table handwheel scale number of 100, providing a clear and precise scale for all your milling tasks. Dual Functionality: Versatile horizontal and vertical operation accommodates a wide range of milling applications, from simple tasks to complex engineering projects. Robust Construction: Made from superior materials, this rotary table ensures exceptional hardness and durability, making it a reliable choice for long-term use. Perfect Fit: The table diameter of 4 in / 100 mm (±2 mm) and chuck diameter of 3.1 in / 80 mm are perfectly matched for efficient milling tasks. Rotary Table Handwheel Scale Value: 6. Worm Gear Ratio: 1:36. Center Height for Vertical Mounting Chuck: 2 in / 50 mm. Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm (±3 mm). Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm. Net Weight: 11.7 lbs / 5.3 kg (± 3%). Enhanced Precision: Perform intricate milling operations with ease and accuracy. Durability and Longevity: Built to withstand rigorous use, ensuring consistent performance over time. Operational Flexibility: Suitable for both horizontal and vertical setups, providing versatility in your workshop. Smooth Operation: Dual-handle design ensures smooth and effortless adjustments for enhanced control. Elevate your milling operations with the VEVOR Precision 4” Rotary Table – the ideal companion for precision engineering and indexing tasks.

4/100 mm Rotary Table Horizontal Vertical with Suitable Round Vices & Clamp Kit

Milling Indexing 4/100 mm Rotary Table Horizontal Vertical with Suitable Round Vices & Clamp Kits. A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. 4// 100 mm Rotary Table. Dual functionality: Can be used horizontally or vertically to accommodate a wide range of machining tasks. Generous 4 inch (100 mm) diameter provides ample space for various workpieces. Smooth rotary motion ensures precise positioning and milling operations. Sturdy construction for durability and long-lasting performance. Compatible with both horizontal and vertical milling machines, enhancing flexibility in your workshop. Precision-machined for exceptional accuracy, delivering reliable results with every use. 3// 80 Round vice. Made of high grade close grain caste Iron. Fits our 3 (75 mm) Rotary Tables perfectly. These vices are drilled in a manner that these can fit to a 3 as well 4 slot table. Diameter of Base : 80 mm Jaw Width : 54 mm Jaw Depth: 20 mm Jaw Opening : 32 mm Height : 29 mm. 4// 100 mm Round vice. Diameter of Base : 100 mm Jaw Width : 79 mm Jaw Depth: 20.5 mm Jaw Opening : 40 mm Height : 33 mm.

3/80 mm Regular Rotary Milling Table ER Collet Adaptor with M6 Clamp Kit- USA

3/80 mm Regular Rotary Milling Table ER Collet Adaptor with M6 Clamp Kit. A rotary table is a precision tool used in machining operations, primarily for rotating a workpiece around a fixed axis, allowing for the accurate machining of circular features, angular positioning, and dividing work into equal sections. 3 (80 MM) Rotary Table 4 Slots. Table Height: 1 5/8. Center Height in Vertical Position: 1. Operates in the Horizontal or Vertical position. Hand Wheel calibrated to 10 degrees per revolution with 1/4 degree increment graduations. Table scale graduated in 5 degree increments. M6 CLAMP KIT. Made of high quality tool steel. These are polished & ground from all sides. Sets includes 2 clamps, 2 blocks, screw of m6 thread with 2 flange nuts & 2 tee-nuts. ER COLLET ADAPTOR. ER Collet adaptor designed for small milling rotary tables. Offers exceptional accuracy of under 5 microns. Compatible with 3″ (80 mm) and 4″ (100 mm) rotary tables. Includes fixing T nuts for secure attachment. Epoxy black finish provides rust resistance and durability. Base plate fits both 3-slot and 4-slot rotary tables seamlessly. Features a 13.9 mm diameter locating spigot for precise centering.

ADI HV 4 Inch II 100mm Rotary Milling Indexing Table with Clamp Kit-USA FULFILL

AD International Horizontal Vertical 4 Inch II 100 mm Rotary Milling Indexing Table with M6 Clamp Kit. A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. 360-Degree Graduation: The table is graduated a full 360 degrees, allowing for precise control and positioning of the workpiece. The clear markings ensure easy and accurate angle setting for all your milling tasks. Worm Gear Ratio: 1:36 The gear ratio means that one full rotation of the handle turns the table by 10 degrees, providing fine control over the movement and ensuring precision in every operation. Vertical Position Center Height: 2-1/16 50 mm approx. The center height in the vertical position is 2-1/16 inches, which aligns perfectly with the smaller milling machine setups, offering versatility in workpiece positioning. Handwheel Graduations: The handwheel is graduated in divisions of 10 minutes, allowing for highly detailed adjustments. The scale can also be set to zero, making it easy to track and repeat your adjustments for consistent results. Mounting Flexibility: The Regular model can be mounted in both horizontal and vertical positions, enhancing its versatility for a wide range of applications. Whether you need flat or angled cuts, this rotary table can handle it with ease. This M6 clamp kit is designed for use with 3″ or 4″ rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning.

Universal Indexing Disc Indexing Table Vertical and Horizontal Fixture

Universal indexing disc indexing table vertical and horizontal dual-purpose rotary disc rotary table hand crank electric turntable fixture. HV series of horizontal and vertical dual-purpose indexing discs (vertical and horizontal rotary table) is the main milling machine. It can be used on the milling machine for indexing drilling or milling, circumferential cutting, boring, countersinking and other work. Cutting, boring, countersinking, etc. On the milling machine. The table has 360° marks, a 1′ scale ring and a 10′ minimum indexing ring. The table has 360° marks and has a 1′ scale ring and a vernier ring with 10′ minimum differentiation. The rotary table is equipped with a brake and indexing worm gear. And indexing worm gears. HV series vertical and horizontal rotary tables in vertical position, with tailstock (special order), can be used for more complex workpieces. In the vertical position, in combination with the tailstock (special order), it is possible to perform circumferential indexing drilling and milling of complex workpieces.

STM 326505 HV-8 8 Horizontal/Vertical Rotary And Dividing Table

Of Comtex Leasing Corp. STM 326505 HV-8 8 Horizontal/Vertical Rotary And Dividing Table.