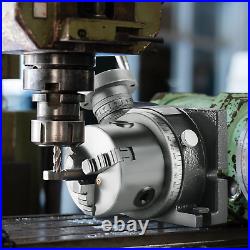

milling

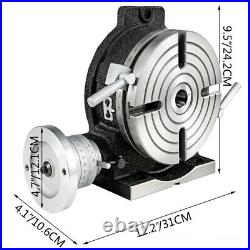

4 Rotary Table 100mm Horizontal Vertical With 4 Slots For Milling

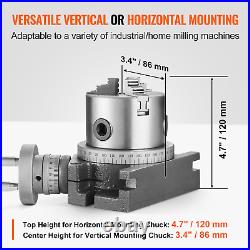

4 Rotary Table 100mm Horizontal Vertical With 4 Slots For Milling. Can be used in both horizontal & vertical position. Table graduated in 360 Degrees. The scale calibrated in 5 degree increment. Hand Wheel calibrated to 10 degree per revolution with 1/4 degree increment graduations.

Horizontal Vertical 4 Inch II 110 mm MT2 Center Bore Rotary Milling Tables

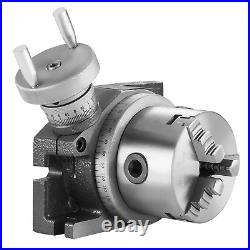

Horizontal Vertical 4 Inch II 110 mm – MT2 Center Bore Rotary Milling Tables. A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. Precision Engineering: Crafted with meticulous attention to detail, our HV4-MT2 Center Bore Rotary Table ensures superior accuracy and performance in your machining operations. Robust Construction: Built with quality materials, this rotary table boasts a sturdy and durable design, providing long-lasting reliability in your workshop. MT2 Center Bore: Features a reliable MT2 center bore, offering secure mounting and precise alignment for your workpieces. Versatile Compatibility: Compatible with a wide range of machining tasks, including milling, drilling, cutting threads, and more, making it a versatile addition to your workshop. Ample Space: With its HV4 size, this rotary table provides ample space for accommodating various workpieces, allowing you to tackle a variety of projects with ease. Easy to Use: Designed for user convenience, this rotary table is easy to set up and operate, ensuring a smooth and efficient workflow in your machining tasks. Professional Grade: Whether you’re a professional machinist or a hobbyist, our HV4-MT2 Center Bore Rotary Table offers professional-grade performance and reliability for all your machining needs. Essential Tool: A must-have tool for any workshop, this rotary table enhances your machining capabilities and helps you achieve precision and accuracy in your projects. Upgrade Your Workshop: Elevate your workshop with the superior performance and versatility of our HV4-MT2 Center Bore Rotary Table, the perfect addition to any machining setup.

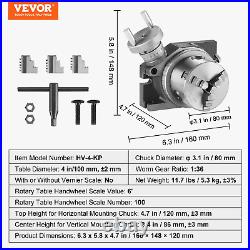

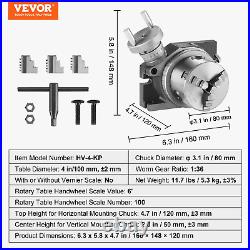

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

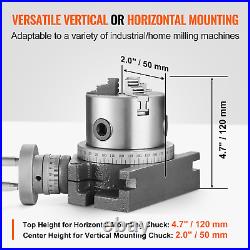

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools 4-Inch Rotary Table for Milling Machine 3-Jaw Chuck Clear Scale Horizontal & Vertical Use Superior Hardness Dual Handle Design Rotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ±3 mm, Rotary Table Handwheel Scale Value: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical Mounting Chuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or Without Vernier Scale: No, Chuck Diameter:? 3.1 in / 80 mm, Table Diameter: 4 in / 100 mm, ±2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm, Net Weight: 11.7 lbs / 5.3 kg ± 3%.

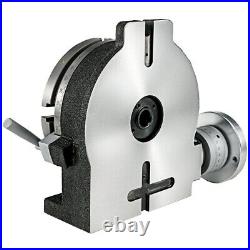

HV5 diameter 125mm vertical and horizontal milling machine horizontal vertical

HV5 diameter 125mm vertical and horizontal milling machine horizontal vertical rotary table high precision. HV series horizontal-vertical indexing plate (vertical-horizontal rotary table) is one of the main accessories of the milling machine, which can be used for indexing drilling or milling, circumferential cutting, boring, countersinking and other work on the milling machine. The worktable has a 360° scale line, a scale ring with a scale value of 1′ and a vernier ring with a minimum differentiation value of 10. The rotary table has a braking and indexing worm shedding mechanism. When the HV series vertical and horizontal turntable is in the vertical position, it can be used in conjunction with the tailstock (special order) to perform circular indexing drilling and milling of more complex workpieces. Made of high-strength FC30 cast iron. Suitable for milling machines or other special machines for cutting and cutting. The new spindle locking system, compared with the traditional bilateral platen type, has stronger locking and more stable cutting. It can be rotated 360 degrees, the handle is rotated 4 degrees, and the minimum scale is drawn for 10 seconds. Can be used in horizontal and vertical directions. Additional special accessories can be made: honeycomb plate and tailstock. Deceleration ratio 1:90.

4 Inches (100 mm) 4 Slots Regular Rotary Table For Milling Machines

Inches (100 mm) 4 Slots Regular Rotary Table For Milling Machines. It will be take w. Because Every feedback is our potential to us.

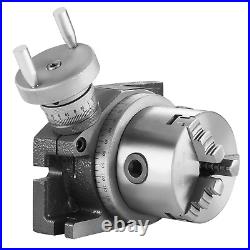

4 Inch / 100 MM Rotary Table With Small Chuck Milling Indexing

4 (100 mm) Rotary Table. Very High Quality 4 /100 mm Regular Rotary Table designed for smaller milling machines. Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16 (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. 65 mm 3 Jaws Self Centering Chuck. 65 mm 3 Jaw Self Centering Lathe Chuck M14 x1 mm. Graded Caste Iron Body and Hardened Tool Steel Jaws. 70 mm 4 Jaws Independent Chuck. 70 mm 4 Jaw Independent Lathe Chuck M14 x1 mm.

HV5 Diameter 125mm Vertical and Horizontal Milling Machine Rotary Table

(HV) TSL type vertical horizontal dividing head is one of the main accessories of milling machine, milling machine can be used in indexing drilling or milling, boring, cutting circular countersink flat etc.. When the working platform is used in conjunction with the tail seat, the more complicated work can be carried out by the circumference of the cutting and milling.

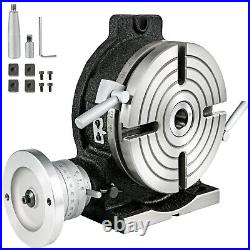

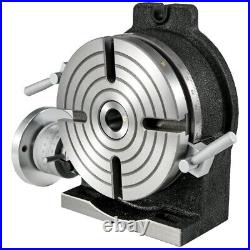

HV 4 Inch II 100 mm Regular Rotary Milling 4 Slots Table (USA Fuffilled)

Made of Caste Iron, Precision High Quality 4 /100 mm Regular Rotary Table designed for smaller milling machines. Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Height when laid horizontally 2-5/16 Inches (58 mm). Center Height in vertical position: 2-1/8 (53.5 mm approx). Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be clamped vertically and horizontally both ways. Base Dimensions : 135 mm x 105 mm with 2 x U slots (9.5 mm). Body is painted and Rest all working surfaces are precision ground. The Dial and locking screws are plated and Handle has epoxy black finish for a rust free life. Smooth Jerk free easy rotation with negligible play. The top of the table is ground to eliminate any excess run out. It is mainly used to cut gear teeth accurately and equal spacing of the teeth of the gear. Also used for milling gears, splines, squares, cutting of flutes in reamers, drills and milling cutters, racks, grinders, etc.

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Table(USA FULFILLED)

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Table. Transform your machining capabilities with our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Engineered for precision and versatility, these rotary tables are designed to elevate your machining projects to new heights. Dual functionality: Can be used horizontally or vertically to accommodate a wide range of machining tasks. Generous 4 inch (100 mm) diameter provides ample space for various workpieces. Smooth rotary motion ensures precise positioning and milling operations. Sturdy construction for durability and long-lasting performance. Compatible with both horizontal and vertical milling machines, enhancing flexibility in your workshop. Precision-machined for exceptional accuracy, delivering reliable results with every use. Whether you’re performing intricate machining tasks or tackling larger projects, our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables deliver the precision and versatility you need for outstanding results. Upgrade your machining capabilities with the precision and versatility of our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Elevate your workshop today!

8 Precision Horizontal and Vertical Rotary Table The Ultimate Milling Companion

Universal 8 Precision Horizontal and Vertical Rotary Table: The Ultimate Milling Companion. Exceptional Quality and Versatility. Universal 8 Precision Horizontal and Vertical Rotary Table. A versatile and high-precision tool designed to elevate your milling, drilling, and boring tasks. Crafted from top-grade HT200 casting, this rotary table promises durability, reliability, and outstanding performance in any workshop. The rotary table is constructed from HT200 casting, a material known for its excellent shock absorption, heat resistance, and high strength. This ensures the table’s longevity and consistent performance, even under demanding conditions. Horizontal and Vertical Use. Designed to be used both horizontally and vertically, this rotary table provides exceptional flexibility. Whether you need to perform circle cutting, indexing drilling, or milling, this table can handle it all. Its dual-functionality makes it an indispensable tool for any serious machinist. 360-Degree Graduated Indexing Plate. Minimum Scale: 10 Seconds. Precision is at the heart of this rotary table’s design. The indexing plate is graduated 360 degrees, allowing for exact positioning. The handle offers 4 degrees per revolution, with a minimum scale marked at 10 seconds. This ensures you can execute even the most complex tasks with unparalleled accuracy. Adjusting the table is straightforward. The dial is clearly marked with an accurate scale, allowing you to quickly set it to the desired position. This user-friendly feature saves time and enhances the efficiency of your work processes. Includes Wrench, Positioning Keys, and Mounting Screws. The Universal rotary table comes with a complete set of accessories, including a wrench, two positioning keys, and mounting screws. These accessories facilitate easy installation and ensure you have everything needed to start working immediately. Wide Range of Applications. Ideal for Milling, Drilling, and Boring. This rotary table is not limited to a single type of task. It’s perfect for a variety of applications such as index boring, milling, circle cutting, spot facing, and boring holes. Its practical design meets diverse workshop needs, making it a versatile addition to your toolkit. 105 mm (4.13 inches). 40 mm (1.57 inches). 1 Wrench, 2 Positioning Keys, 2 Mounting Screws, 1 Vertical and Horizontal Rotary Working Table. Why Choose the Universal 8 Precision Rotary Table? Unmatched Quality and Precision. Crafted from durable HT200 casting, this rotary table offers remarkable quality. Its precision engineering ensures exacting standards for all your machining tasks. The ability to use the table both horizontally and vertically expands its usability, allowing you to tackle a wide range of projects with a single tool. With easy-to-read scales and straightforward adjustments, this rotary table is designed to enhance your workflow and reduce setup time. The inclusion of essential accessories means you’re ready to go right out of the box, adding convenience and value. Upgrade your workshop with the. Experience the perfect blend of durability, precision, and versatility in one exceptional tool. Get yours today and take your machining projects to the next level!