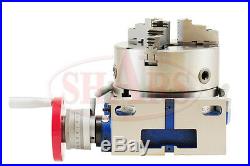

10 Horizontal and Vertical ROTARY TABLE With 10 3 JAW Self Centering Chuck

SHARS 10″ HIGH QUALITY H / V ROTARY TABLE W/ 10″ 3 JAW SELF CENTERING CHUCK NEW. Why Shars Brand rotary table has higher TIR than other Brand? There is center align pin come with Shars Brand rotary table. Located by chuck’s jaws, high TIR. The tools’s TIR reaches Chuck’s TIR 0.003 and rotary table’s TIR when you turn the handle to divide degree, because the center of tools and the center of chuck are coincide. There is no center align pin with other’s brand rotary table, only come with screws. The tools’ TIR can’t be guaranteed when you turn the handle to divide degree, because the center of tools and the center of chuck are’t coincide. The rotary table has no TIR, so only low TIR tools can be machined. Same quality, we also sell PHASE II brand. Chuck could connect 10 rotary table directly. Compare with PHASE II brand. If set up an 10. Table diameter: 9.84. Horizontal O/A Height: 4.53. Center height vertical position: 6.49. Overall height in vertical position: 12.79′. Overall width (not including handle) in vertical position: 11.02′. Mounting table bolt width: 0.63′. T-slot width: 0.55′. Center taper: Morse Taper 3. Without coolant pathway on rotary table base to catch the coolant. Mounting: Front Mounting & Plain back. Center hole: 3.15. Bolt Circle Diameter: 8.898. 10 second vernier reading. Gear drive immersed in oil. Dual positive action locks. Maximum individual spacing error 4″ table 120″, 6″ table 80″, 8, 10, 12, 16″ tables 60″. 4 table utilizes low profile locks for added workspace. Gear ratio: 4″ table is 72:1; 6-16″ tables are 90:1. Flatness of clamping service-concave. Concentricity of center bore. Parallelism of clamping surface to angle face. Squareness of angle surface to clamping surface. Squareness of clamping surface to center slot. Semi-steel chuck body made from high quality cast iron. Three pinion design with each pinion ground and hardened to HRC 43. Two piece jaw design with a master jaw and a top reversible jaw in American Standard tongue and groove specification. Both side of jaw teeth and guides are ground and hardened to HRC 58-62. Each set of jaws are serialized in their own set. A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy. Before assembling the jaw to its designated chuck body, the jaw’s finish machining are performed on a closed tolerance state of the art CNC machine from Japan. Scroll plate’s thread flank are ground on both side to achieve a tighter contact with the master jaw. Each chuck has gone through rigorous accuracy and repeatability inspection with clamping and jamming multiple random testing rods or rings. Accuracy is maintained for the entire clamping range. 1 set of reversible jaws for inside and outside. 6 piece of mounting screws for the lathe chuck back plate (3 screws for front mounting and 3 screws for back mounting). SHARS Tailstock for 8″ 10″ 12 Rotary Table MT No. The item “10 Horizontal and Vertical ROTARY TABLE With 10 3 JAW Self Centering Chuck” is in sale since Monday, June 5, 2017. This item is in the category “Business & Industrial\CNC, Metalworking & Manufacturing\Workholding & Toolholding\Workholding\Rotary Tables”. The seller is “discount_machine” and is located in Saint Charles, Illinois. This item can be shipped to United States.

- MPN: 202-2027

- Brand: Shars Tool