rotary

HV 4 Rotary Table With 70 mm 4 Jaw Independ Chuck Lathe + Back plate EDGETOOLS

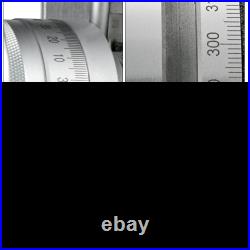

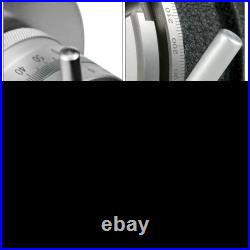

HV 4 Rotary Table With 70mm 4 Jaw Independent Chuck Lathe + Back Plate. Rotary Table 70mm 4 Jaw Independent Chuck. Chuck Diameter 4? (100 mm). Vertical Center Height 2-1/16? Approx. Hand Wheel can be set to zero. Hand Wheel graduated in 10 min divisions. Cali berated in 5 min increment around the rim. Can be used both Horizontally & Vertically. 70mm 4 Jaw Independent Chuck. Quality 4 jaw small independent chuck 70 mm Diameter. Reversible jaw adjustment mechanism. Thread – M14 X 1. Backplate is drilled and counterbored to fit a range of 3″ and 4″ rotary tables with 4 Slots. Supplied complete with a key as well as set of tee nuts and studs to secure it into place. PROUDLY MADE IN INDIA. ? EDGE TOOLS comprises of a dedicated and skilled team of engineers with an aim of providing you tools of highest indian industrial standards. Situated at the industrial hub of. We specialize in providing complete tooling solutions. Our Motto : Right Quality. We ensure the product reaches you at the earliest. Follow Us On Instagram User Id – Rahishtools And To Shop For Great Deals. We are looking forward to your positive reviews and to build a long term relationship.

3 Rotary table combo -Collet, Round Vice, Tailstock, Clamp KIt, Chuck & Back Plate

ROTARY TABLE 3/80 MM WITH ER16 COLLET ADAPTOR, M6 CLAMP KIT, ROUND VICE, TAILSTOCK &. 70 MM 4 JAW INDEPENDENT CHUCK WITH BACK PLATE & FIXING TNUTS. This is a comprehensive Rotary Table Workholding Set designed for precision milling and indexing operations. It includes a high-quality 3 (80 mm) rotary table bundled with essential accessories to enhance your machining capabilities. 3 (80 mm) Rotary Table – Horizontal Use. 70 mm 4-Jaw Independent Chuck with Back Plate. Worm Gear Ratio: 36:1 – One complete turn of the handle rotates the table by 10 degrees, allowing precise indexing. Total Assembly Height: Approx. 80 mm (Table + ER16 Collet Adapter). Refer to the photo for a visual reference. ER16 Collet Adapter: Allows secure and accurate holding of tooling and components for fine machining. Mounting Compatibility: The adapter’s base is M6 drilled to fit both 3-slot and 4-slot rotary tables, ensuring versatile use. Sturdy Tailstock: Ideal for supporting long workpieces, ensuring minimal deflection during operation. 4-Jaw Independent Chuck: Comes with a back plate and fixing T-nuts to mount securely on the rotary table for irregular or square jobs. Clamp Kit: Enables easy and firm clamping of workpieces during milling and drilling operations. This set is ideal for hobbyists, toolmakers, model engineers, and machinists looking for a complete and ready-to-use solution for rotary indexing, angular drilling, or gear cutting.

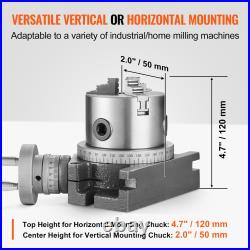

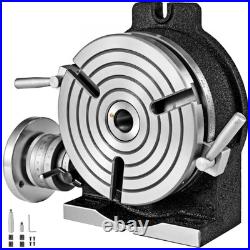

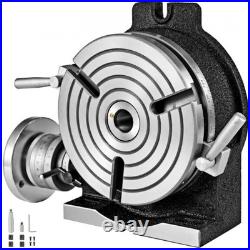

Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Mach

VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3.

3 Rotary table

The 3 Rotary table by KBC Tools is a versatile tool for CNC, metalworking, and manufacturing industries. This manual rotary table can operate in both horizontal and vertical settings, providing precision and stability for various workholding and toolholding applications.

6HV Rotary Table 4 slots with Indexing Plates Set and Adjustable Tailstock

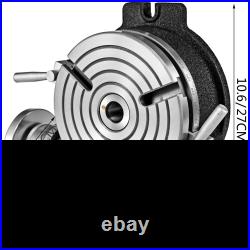

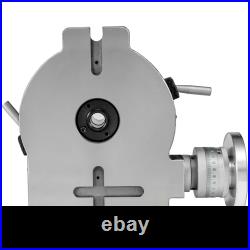

Upgrade your machining capabilities with this high-precision 6 Rotary Table featuring an Indexing Plates Set for accurate dividing, indexing, and circular machining. Designed for both horizontal and vertical mounting, this rotary table is perfect for milling, drilling, slotting, and gear cutting applications. The included indexing plates allow for precise angular division, making it an essential tool for machinists, metalworkers, and DIY enthusiasts. 6 Precision Rotary Table. Built from high-grade cast iron with precision-ground components for smooth operation. Indexing Plates Set Included – Achieve accurate angular divisions for gear cutting, bolt hole patterns, and complex machining tasks. Horizontal & Vertical Mounting – Can be positioned flat or upright for versatile applications. 360° Graduated Scale with Vernier Calibration – Enables ultra-fine adjustments for high precision. 90:1 Gear Ratio – One full turn of the handwheel moves the table by 4°, allowing for precise machining control. 4-Slot T-Table Design – Compatible with various clamping and fixture setups for secure work-holding. Smooth Hand-wheel Operation – Equipped with adjustable backlash to maintain accuracy over time. 90:1 (1 full handwheel rotation = 4° movement). Standard 10mm slots for secure clamping. Yes, full set for precision dividing. Center Height (Vertical Position). High-grade cast iron with hardened and precision-ground components. Plate A : 15, 16, 17,18, 19, 20. Plate B : 21, 23, 27, 29, 31, 33. Plate C : 37, 39, 41, 43, 47, 49. Center Height Range : Adjustable to match HV4 & HV6 rotary table (80mm to 110mm) height. Material : Cast Iron Body with Ground Steel Components. Base : Slotted for secure mounting on the machine table. Milling, drilling, and grinding. Indexing & dividing for gear cutting, hole patterns, and precision machining. Engraving, slotting, and circular cutting. Metal & woodworking projects. Custom machining setups requiring precise rotation and angular positioning. Supports long shafts and work-pieces during rotation. Perfect for use with dividing heads and rotary tables in horizontal setups. Improves accuracy and reduces deflection during machining. 1 x 6 Rotary Table. 1 x Indexing Plates Set. (3 plates for different divisions). 1 x Adjustable Tailstock. Why Choose This Rotary Table? Perfect for professionals and hobbyists alike. Versatile Mounting – Use in both horizontal and vertical positions. Enhanced Indexing Functionality – Divide work-pieces with accuracy using the indexing plates. Durable & Reliable – Built for long-lasting performance with heavy-duty materials. Great Value – High-quality milling accessory at a competitive price. We are looking forward to your positive reviews & to build a healthy relationship.

Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn.

Rotary Table 4 Inch/100 mm Horizontal Vertical For Milling Premium Quality

Rotary Table 4 100mm Horizontal Vertical Model Milling Machine 4 Slots. The Metal : High quality 18 Gauge Mild Iron steel with Brass Accents. THIS NEAT LITTLE ROTARY TABLE, WITH A DIAMETER OF 100MM, CAN BE USED FOR A VARIETY OF MILLING, DRILLING AND MARKING OUT OPERATIONS IN THE HOME ENGINEER’S WORKSHOP. THERE ARE FOUR TEE SLOTS FOR SECURING THE WORK, FACES MACHINED AT RIGHT ANGLES FOR HORIZONTAL AND VERTICAL MOUNTING AND 7MM SLOTS FOR SECURING TO THE MACHINE TABLE. THE INDEXING HANDLE, WHICH ROTATES ONCE FOR EVERY TEN DEGREES OF TABLE ROTATION, IS SUBDIVIDED IN DEGREES AND QUARTER DEGREES. THE CENTRE HEIGHT WHEN MOUNTED VERTICALLY IS 40MM. SUPPLIED WITH WORK CLAMPING KIT. VERTICAL AND HORIZONTAL MOUNTING TEE SLOTS FOR SECURING WORK WHEEL MARKED IN DEGREES AND QUARTER DEGREES. A Precision work positioning device used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis. Rotary tables are most commonly mounted “flat”, with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. An alternate setup is to mount the rotary table on its end (or mount it “flat” on a 90° angle plate), so that it rotates about a horizontal axis. In this configuration a tailstock can also be used, thus holding the work piece between centers. Horizontal/Vertical Rotary Tables are extremely useful accessories for a milling machine. Milling curved profiles and angled faces relative to a centre line. Drilling or milling to polar co-ordinates and, when mounted vertically with a tailstock they can be used to machine shafts or spindles. The versatile units can also be used on drilling, boring or slotting machines permitting an even greater range of operations. Machining – To establish the initial work piece position simply loosen the zero Collar locking handle and rotate the zero collar anti-clockwise for about half A turn. The worm is now disconnected from the worm wheel drive, the table is Free to turn independently to the crank handle and the work piece may now be Accurately aligned. To re-engage simply turn the zero collar in the clockwise Direction and re-tighten the locking handle. To machine spanner flats on a bolt. To drill equidistant holes on a circular flange. To cut a round piece with a protruding tang. To create large-diameter holes, via milling in a circular tool path, on small milling machines that don’t have the power to drive large twist drills (>0.500/>13 mm). To cut complex curves (with proper setup). To cut straight lines at any angle. The holiday season is the busiest shopping period of the year, don? Our catalog covers every festival including Thanksgiving, Black Friday, Cyber Monday, Christmas. Please do visit our store and get yourself a treat.

Rotary Table Boring Accurate Positioning Indexing Disc Horizontal Vertical

Rotary Table Boring Accurate Positioning Indexing Disc Horizontal Vertical. Versatile Functionality? : The rotary table is designed for both horizontal and vertical use, making it an essential accessory for milling machines. It is great for indexing drilling, milling, circular cutting, and countersinking tasks? Construction? : Crafted from quality iron material, this rotary table for milling ensures long time durability and reliable performance in various machining applications? Compact Dimensions? : This milling table is compact yet efficient, fitting seamlessly into your workspace without compromising on functionality? Package? : The package includes what you need to get started – the machine itself, four T shaped nuts, 1 pressure plate screw, 1 handle crank, and 2 positioning keys? Essential Milling Accessory? : Enhance your milling machine’s capabilities with this indispensable tool that supports a wide range of machining operations with precision and ease. Style A: 7.8cmx9.8cm/3.07inchx3.86inch, Disc diameter 7.5cm/2.95inch Style B: 11.4cmx14.5cm/4.49inchx5.71inch, Disc diameter 11cm/4.33inch, Middle hole 1.6cm/0.63inch. 1 Rotary Table 4 T nuts 1 Pressure plate screw 1 Crank 2 Positioning keys. Please pay what you win in 7 days. Because the unpaid dispute will not be closed automatically, and we may ignore it. Please verify your address during checkout. We are not responsible for any wrong or undeliverable addresses. We are committed to give you the best customer service possible. Please let us work on the issues. We’d like to settle any problem in a friendly manner. Due to the difference of time zone between Hong Kong and your location, sometimes the answer will be delayed. It’s just take you 1 minute. People always bought together with.

Rotary Table 8 Inch 200MM Horizontal Vertical 3 Slot For Milling Tool

8/200mm Rotary Table 3-Slot Horizontal Vertical Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. 8 Vertical & Horizontal Design. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Free Wrench & Screw. A wrench and screws are free for you with your installation the vertical & horizontal rotary table. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Table Diameter: 8/200mm. Reduction ratio: 1:90. Horizontal Height : 4.13/105mm. Vertical Height : 1.57/40mm. 1 x Vertical and Horizontal Rotary Working Table. 1 x Screw Set.

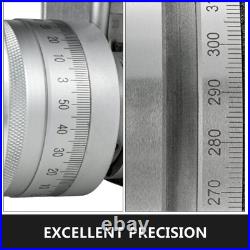

8 Rotary Table MT3 Horizontal Vertical 3-Slot 360° for Milling Machine

Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary Table for Milling Machine MT-3 Rotary Table for Milling 360 Degrees Precision Rotary Table. 8″ Vertical & Horizontal Design: Our rotary table for milling machine is 8″ / 200 mm with 3 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. Excellent Precision: The precision rotary table’ indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: With free wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Free Wrench & Screw Various Application Vertical Height : 1.57″/40mm, Horizontal Height : 4.13″/105mm, Material: HT200 Casting, Table Diameter: 8/200mm, Reduction ratio: 1:90, Center Bore: MT-3.