rotary

New ADJ 4 inch 100mm Tilting Tailstock & Rotary Table Tilting Dividing Head USA

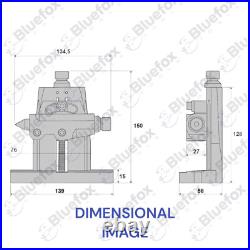

Description For 4 inches 100mm Tilting 0°- 90° Rotary Table Milling Machine Tool. 4 100mm Tilting Rotary Table. Features to Tilt between 0 – 90 degrees and can be locked at any position. Table diameter 100mm table is graduated 360 degrees. Worm gear ratio 1:36 which means that 1 handle rotation shall turn the table by 10 degrees. Centre height in vertical position: 2-5/8 (66mm approx) hand wheel is graduated in division of 10 minuend can be set at Zero. Can be mounted in Horizontal & Vertical position. Tip hardness [HRC] 40 – 45. Material tip C45E steel. Net weight [kg] 2.4. Center height [mm] 45 – 80. Tip Ø [mm] 15. Dimensions base [mm] 140 X 57. Total height [mm] 155. Thanks to the height-adjustable tip, this tailstock is suitable for dividing heads whose center of the rotary table is between 45 and 80 mm in a vertical position. In order to achieve a horizontal alignment of the workpiece, it is clamped between the dividing head and the tailstock. The tailstock center is fixed at the set height using a clamping screw, and the horizontal position of the center can also be secured by clamping. The lateral adjustment of the centering tip is made possible by a knurled rotary knob. The horizontal travel of the tip is 27 mm. PROUDLY MADE IN INDIA. Skylark Tools comprises of a dedicated and skilled team of engineers with an aim of providing you tools of highest Indian industrial standards. Situated at the industrial hub of India we specialize in providing complete tooling solutions. Our Motto: Right Quality. The Motto of the Company is to deliver the best products and services to the customers at most competitive prices. We ensure the product reaches you at the earliest. We are looking forward to your positive reviews and to build a long term relationship.

6HV Rotary Table 4 slots with Indexing Plates Set and Adjustable Tailstock

Upgrade your machining capabilities with this high-precision 6 Rotary Table featuring an Indexing Plates Set for accurate dividing, indexing, and circular machining. Designed for both horizontal and vertical mounting, this rotary table is perfect for milling, drilling, slotting, and gear cutting applications. The included indexing plates allow for precise angular division, making it an essential tool for machinists, metalworkers, and DIY enthusiasts. 6 Precision Rotary Table. Built from high-grade cast iron with precision-ground components for smooth operation. Indexing Plates Set Included – Achieve accurate angular divisions for gear cutting, bolt hole patterns, and complex machining tasks. Horizontal & Vertical Mounting – Can be positioned flat or upright for versatile applications. 360° Graduated Scale with Vernier Calibration – Enables ultra-fine adjustments for high precision. 90:1 Gear Ratio – One full turn of the handwheel moves the table by 4°, allowing for precise machining control. 4-Slot T-Table Design – Compatible with various clamping and fixture setups for secure work-holding. Smooth Hand-wheel Operation – Equipped with adjustable backlash to maintain accuracy over time. 90:1 (1 full handwheel rotation = 4° movement). Standard 10mm slots for secure clamping. Yes, full set for precision dividing. Center Height (Vertical Position). High-grade cast iron with hardened and precision-ground components. Plate A : 15, 16, 17,18, 19, 20. Plate B : 21, 23, 27, 29, 31, 33. Plate C : 37, 39, 41, 43, 47, 49. Center Height Range : Adjustable to match HV4 & HV6 rotary table (80mm to 110mm) height. Material : Cast Iron Body with Ground Steel Components. Base : Slotted for secure mounting on the machine table. Milling, drilling, and grinding. Indexing & dividing for gear cutting, hole patterns, and precision machining. Engraving, slotting, and circular cutting. Metal & woodworking projects. Custom machining setups requiring precise rotation and angular positioning. Supports long shafts and work-pieces during rotation. Perfect for use with dividing heads and rotary tables in horizontal setups. Improves accuracy and reduces deflection during machining. 1 x 6 Rotary Table. 1 x Indexing Plates Set. (3 plates for different divisions). 1 x Adjustable Tailstock. Why Choose This Rotary Table? Perfect for professionals and hobbyists alike. Versatile Mounting – Use in both horizontal and vertical positions. Enhanced Indexing Functionality – Divide work-pieces with accuracy using the indexing plates. Durable & Reliable – Built for long-lasting performance with heavy-duty materials. Great Value – High-quality milling accessory at a competitive price. We are looking forward to your positive reviews & to build a healthy relationship.

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Indexing Table with M6

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. A clamp kit for a rotary table is used to secure workpieces onto the rotary table during machining operations. Rotary tables are often used in machining setups to enable circular cutting, hole drilling, and other operations around a fixed axis of rotation. 360-Degree Graduation: The table is graduated a full 360 degrees, allowing for precise control and positioning of the workpiece. The clear markings ensure easy and accurate angle setting for all your milling tasks. Worm Gear Ratio: 1:36 The gear ratio means that one full rotation of the handle turns the table by 10 degrees, providing fine control over the movement and ensuring precision in every operation. Vertical Position Center Height: 2-1/16 (50 mm approx) The center height in the vertical position is 2-1/16 inches, which aligns perfectly with the smaller milling machine setups, offering versatility in workpiece positioning. Handwheel Graduations: The handwheel is graduated in divisions of 10 minutes, allowing for highly detailed adjustments. The scale can also be set to zero, making it easy to track and repeat your adjustments for consistent results. Mounting Flexibility: The Regular model can be mounted in both horizontal and vertical positions, enhancing its versatility for a wide range of applications. Whether you need flat or angled cuts, this rotary table can handle it with ease. This M6 clamp kit is designed for use with 3″ or 4″ rotary tables. Includes a set of clamps, bolts, nuts, and T-slot nuts. Compatible with rotary tables featuring M6 T-slots or mounting holes. Allows for secure fastening of workpieces onto the rotary table during machining operations. Made of tool steel for durability and reliability. Provides essential holding power to maintain precision and accuracy. Ideal for use in machining setups requiring precise rotary table positioning.

Tsudakoma RNCM-301R 12 Rotary Table / 4th Axis

The Tsudakoma RNCM-301R 12 Rotary Table / 4th Axis is a high-quality CNC-controlled workholding unit manufactured by Tsudakoma in Japan. This rotary table allows for horizontal and vertical setting positions, making it versatile for various manufacturing needs. With a 12 diameter and a sturdy construction, this unit is designed to provide precise and reliable performance for metalworking and manufacturing applications.

Horizontal Vertical Red Beam Rotary Laser Level with Receiver and Remote

Horizontal Vertical Red Beam Rotary Laser Level with Receiver and Remote. Comes with receiver, remote, glasses, and carry case.

High Precision CNC Rotary Table with Stepper Motor

High Precision CNC Rotary Table with Stepper Motor.

Buyohlic Horizontal Vertical HV8 8 (200 mm) -3 slots Rotary Milling Indexing

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. Upgrade your machining capabilities with our HV8 Rotary Table, designed for high precision and durability. Ideal for both professional and hobbyist applications, this rotary table is built to handle diverse machining tasks with ease and accuracy. Disc Diameter : 200 mm – Optimized for a wide range of setups and part sizes. Turbine Worm Speed Ratio : 1:90 – Ensures smooth, controlled rotation, perfect for precision work. Vertical Center Height : 135 mm – Accommodates varied machining needs, making it a versatile addition to your setup. Weight : 30 kg – Stable and robust, it minimizes vibrations, enhancing accuracy. Constructed with premium materials, this HV8 rotary table withstands heavy-duty use while maintaining consistent, reliable performance. Its 3-slot design allows for secure, versatile clamping of workpieces, ensuring ease of use across various machining applications. The 1:90 gear ratio provides precise control over positioning, making it well-suited for detailed work that requires accuracy. The compact yet sturdy design fits seamlessly into your workspace, allowing for flexibility whether working on vertical or horizontal setups. Perfect for milling, drilling, and even more complex operations like engraving or machining circular parts.

Lot of 5 Precision Machining Rotary Tables & Chucks & 4 Face Plates 320mm ts320A

Lot of 5 Precision Machining Rotary Tables & Chucks & 3 Face Plates, Everything came from a local machine shop and im not a machinist so this stuff is foreign to me, see images for more info. Most have no brand names that I can find but a more detailed description of each is below. Rotary table (green base) with chuck, is stamped made in japan (3 jaw 8/210mm chuck). Largest one is a 320mm. Rotary table with face plate, name plate is in. Has a micrometer turning handle that spins the table. 4 Jaw 10 chuck (No markings) has screws coming out bottom. Amestra 11 3/4 3 jaw chuck, plain back. 4 Round face plates, No markings on any them (2) 16″ (2) 15″, 1 has a lot rust, 1 have some, others look ok.

HV 4 (100 mm) Tilting Milling Indexing Horizontal Vertical Rotary Table with

Use of product – A rotary table is a precision work positioning device used in metalworking. It enables the operator to drill or cut work at exact intervals around a fixed (usually horizontal or vertical) axis. A round vise is used for securely holding round or cylindrical workpieces during machining, drilling, grinding, or inspection processes. Its design allows for stable and precise positioning, facilitating accurate and consistent operations on the workpiece. 4 (100 mm) Rotary Table. 360-Degree Graduation: The table is graduated a full 360 degrees, allowing for precise control and positioning of the workpiece. The clear markings ensure easy and accurate angle setting for all your milling tasks. Worm Gear Ratio: 1:36 The gear ratio means that one full rotation of the handle turns the table by 10 degrees, providing fine control over the movement and ensuring precision in every operation. Vertical Position Center Height: 2-1/16 (50 mm approx) The center height in the vertical position is 2-1/16 inches, which aligns perfectly with the smaller milling machine setups, offering versatility in workpiece positioning. Handwheel Graduations: The handwheel is graduated in divisions of 10 minutes, allowing for highly detailed adjustments. The scale can also be set to zero, making it easy to track and repeat your adjustments for consistent results. Mounting Flexibility: The Regular model can be mounted in both horizontal and vertical positions, enhancing its versatility for a wide range of applications. Whether you need flat or angled cuts, this rotary table can handle it with ease. Made form Quality close grain Caste Iron -Designed to fit our 3″ (75 mm) & 4″(100 mm) Rotary Tables. Diameter of Base : 80 mm Jaw Width : 54 mm Jaw Depth: 20 mm Jaw Opening : 32 mm Height : 29 mm. These vices are counter- drilled in a manner that these can fit to a 3 as well 4 slot table. The moving jaw has V-grooves to hold Round objects. Precisely Ground on Base, Top, Jaws & Base. Rest Body is painted for a long rust free life. 100 mm Diameter Caste Iron Round Vise vice -Made from Close grain Caste Iron. Designed to fit our 4 (100 mm) Regular & tilting models of Rotary Table. Vice is counter drilled in a manner that it can fit to both 3 as well as 4 Slots Rotary Table. Diameter of Base : 105 mm Jaw Width : 75 mm Jaw Depth: 21 mm Jaw Opening : 40 mm Height : 32 mm.