vertical

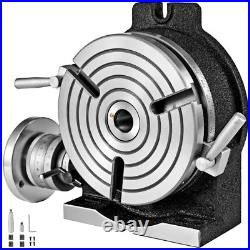

Milling Indexing 4/ 100 Mm Rotary Table Quality Precision Horizontal Vertical W

Set Of Quality 4 Inches/ 100 MM Regular Rotary Table With Suitable M6 Clamp Kit & 80 Mm Round Vises/ Vices. Table Diameter Is 4 / 100 MM & Is Graduated 360 Degrees. Worm: Gear Ratio Is 1: 36, Which Means 1 Handle Rotation Turns The Table By 10 Degrees. Center Height In Vertical Position 2-1/16/ 50 MM (Only The Table). It Can Be Mounted Horizontally And Vertically. Supplied With A Clamp Kit & Quality Caste Iron 80 Mm Diameter Round Vice With Clamping T Nuts. The Moving Jaw Has Vertical & Horizontal V Grooves To Hold A Round Job. Description of 4 (100 mm) rotary table designed for smaller milling machines. Table diameter 100 mm table is graduated 360 degrees. Worm gear ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 degrees. Center height in vertical position: 2-1/16 (50 mm approx). Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in horizontal & vertical position. Details of round vice: details of round vice: 80 mm round vice – made of high grade close grain caste iron. Designed to fit our 3″ (75 mm) & 4″ (100 mm) rotary tables. The moving jaw has v-grooves to hold round objects. Again these vices are drilled in a manner that these can fit to a 3 as well 4 slot table. The drills are counter bored to ensure that the fixing screws sets perfectly ensure perfect movement. Diameter of base : 80 mm jaw width : 54 mm jaw depth: 20 mm jaw opening : 32 mm height : 29 mm.

12 Yuasa Type 550 Horizontal & Vertical Rotary Table Stock 19680

12 YUASA TYPE 550 HORIZONTAL & VERTICAL ROTARY TABLE: STOCK 19680.

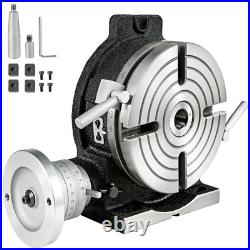

Vevor Rotary Table 4 Inch 100 MM Horizontal Vertical Rotary Table 4 Slot Rotary Table For Milling Ma

Horizontal Vertical 4 Inch II 100 mm MT2 Center Bore Tilting Rotary Milling

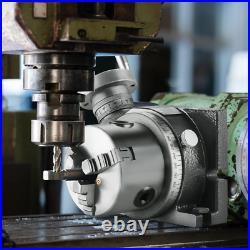

Precision Engineering: Crafted with meticulous attention to detail, our HV4-MT2 Center Bore Rotary Table ensures superior accuracy and performance in your machining operations. Robust Construction: Built with quality materials, this rotary table boasts a sturdy and durable design, providing long-lasting reliability in your workshop. MT2 Center Bore: Features a reliable MT2 center bore, offering secure mounting and precise alignment for your workpieces. Versatile Compatibility: Compatible with a wide range of machining tasks, including milling, drilling, cutting threads, and more, making it a versatile addition to your workshop. Ample Space: With its HV4 size, this rotary table provides ample space for accommodating various workpieces, allowing you to tackle a variety of projects with ease. Easy to Use: Designed for user convenience, this rotary table is easy to set up and operate, ensuring a smooth and efficient workflow in your machining tasks. Professional Grade: Whether you’re a professional machinist or a hobbyist, our HV4-MT2 Center Bore Rotary Table offers professional-grade performance and reliability for all your machining needs. Essential Tool: A must-have tool for any workshop, this rotary table enhances your machining capabilities and helps you achieve precision and accuracy in your projects. Upgrade Your Workshop: Elevate your workshop with the superior performance and versatility of our HV4-MT2 Center Bore Rotary Table, the perfect addition to any machining setup.

VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. Remarkable Quality: HT200 Casting is mainly uséd to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be uséd in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely uséd in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely uséd for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is uséd together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table. Enhance Your Milling Projects – Vertical Rotary Table. Elevate your milling and drilling accuracy with the VEVOR 8-inch horizontal vertical rotary table. It is crafted from durable HT200 casting. This versatile table has a 360-degree indexing plate and a finely calibrated dial. This offers unmatched precision. Whether you’re a hobbyist or a professional, this table is ideal. Its easy setup makes it accessible to users of all skill levels. The wide range of applications makes it indispensable for achieving exceptional results in your workshop. You can experience a rotary table built for performance and longevity. Heat Dissipation for Safety. Safety is important when working with machinery. This 8-inch rotary table boasts high heat dissipation capability. This ensures it performs consistently even under high-stress conditions. The result is equipment that does not wimp on any job; this milling, drilling and boring table stands firm. Its efficient heat dissipation system prevents overheating. This minimizes burn risks and ensures consistent performance even under demanding conditions. Flexible Build – Maximum Versatility. A flexible table means you can work on different projects with one piece of equipment. This rotary table can be tilted in horizontal and vertical positions. The VEVOR rotary table will give you the flexibility needed for diversified projects. Be it milling circular shapes or drilling accurate holes, this 8-inch rotary table can be turned to your needs. Hence, an easier and more convenient workflow is guaranteed. This saves you time and effort while ensuring precision in your projects. A precise machine will produce perfect results every time. The VEVOR precision milling machine table has high accuracy ratings. It has a 360-degree indexing plate and a finely resettable dial that ensures it. Thus, it gives precise measurements and accurate results for your projects. The minimum scale reads down to 10 seconds. So with this rotary table, you are guaranteed to get all the measurements you need for your projects. This ensures that your workpieces meet the highest standards of quality. Easy to Setup & Adjust. An easy-to-set-up machine means you can get its benefits quickly. Setting up this horizontal vertical rotary table is easy. An accurate scale on the dial and an intuitive control handle allows for adjustments to be easy and quick to make without hassle. The setup is pre-oiled, which is why it is easy to get things going right away. This design simplicity lets even beginners work wonders with a rotary table the first time around. There is no need for extensive setup or adjustments. You can start using the rotary table immediately. Durable equipment will last long. This rotary table, made from HT200 casting, is a testament to this. It will surely be a good companion for any serious miller, driller, or borer. The high-grade casting of cast iron in this device offers longevity and brilliant shock resistance. This ensures your rotary table is secure and long-lasting. This heavy-duty construction and fine craftsmanship will make it a reliable companion in the workshop. It has smooth operation and a sturdy build that holds up pretty well even to regular usage. The fit and finish of this table are exceptionally good. It could be uséd for both hobbyists, and professional needs. Wide Range of Applications. One machine should be needed to handle different projects. From index boring to circle cutting, the VEVOR precision milling machine table is highly versatile. It’s designed to meet various workshop requirements. Hence, it is suitable for milling, drilling, and boring. You can use it for everything from optic cuts on slides to fabricating mounts. It has the capacity to do both simple and complex projects. This makes it an ideal and versatile tool for any workshop. Specifications: – Length: 39.0 in, Width: 32.5 in, Height: 19.0 in. Sorry, our items are NOT available for pick-up. No additional information at this time. You might also like. VEVOR Grease Pump, 50:1 Pressure Ratio Air Operated Grease Pump with 13 ft High.

4”/100mm Rotary Table for Milling Machines Horizontal Vertical Model Precisio

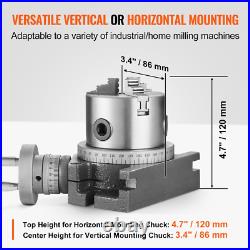

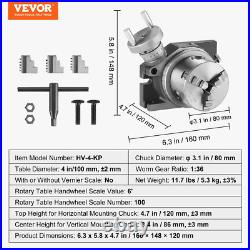

Upgrade your milling machine with the VEVOR 4”/100mm Rotary Table for enhanced precision and versatility. This rotary table is designed to provide superior performance, whether you need horizontal or vertical mounting. It comes with a 3.1”/80mm 3-Jaw Chuck and M10 T-Bolts Nuts, making it suitable for various milling applications in engineering and indexing tools. With a clear scale, dual-handle design, and top-notch hardness, this rotary table is engineered for accuracy and durability. Get precise measurements thanks to the handwheel scale number of 100 and the worm gear ratio of 1:36. The chuck diameter is? 3.1 in / 80 mm, while the table diameter is 4 in / 100 mm. The top height for horizontal mounting chuck is 4.7 in / 120 mm, and the center height for vertical mounting chuck is 2 in / 50 mm. The VEVOR 4”/100mm Rotary Table weighs 11.7 lbs / 5.3 kg ± 3% and has dimensions of 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm. Specifications: – Length: 19.0 in, Width: 17.0 in, Height: 18.0 in.

VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary

VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary Table for Milling Machine MT-3 Rotary Table for Milling 360 Degrees Precision Rotary Table. 8″ Vertical & Horizontal Design: Our rotary table for milling machine is 8″ / 200 mm with 3 slots can be uséd in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly uséd to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. Excellent Precision: The precision rotary table’ indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: With free wrench and set of screws, the power milling machines are widely uséd in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8/200mm Rotary Table 3-Slot Horizontal Vertical Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely uséd for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. 8 Vertical & Horizontal Design. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is uséd together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Free Wrench & Screw. A wrench and screws are free for you with your installation the vertical & horizontal rotary table. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Table Diameter: 8/200mm. Reduction ratio: 1:90. Horizontal Height : 4.13/105mm. Vertical Height : 1.57/40mm. 1 x Vertical and Horizontal Rotary Working Table. 1 x Screw Set. Rotary Table Offers Exceptional Quality and Accuracy at a Great Price. This VEVOR rotary table combines high quality with great precision. The HT200 casting material ensures durability. Users can expect smooth, accurate movements for all milling needs. Fine machining on the table’s surface and internals reflects excellent craftsmanship. This rotary table provides an affordable solution without compromising on accuracy or build. It aligns perfectly when mounted. It offers precise cuts and movements. That is surprising because it has a low price point. Even beginners will find the accuracy plus quality more than enough. For the price, you’re getting a high-performing, reliable rotary table. Smooth Operation and Well-Built Structure Enhance User Experience. The VEVOR rotary table is smooth and easy to operate. Its well-built nature ensures a pleasant user experience. The mechanisms work without issues. Hand wheel rotation and table rotation are seamless. Finely machined surfaces enhance work efficiency. This ease of use makes it appealing for various milling tasks. All components work harmoniously. Users will find the structure strong and long-lasting. So, users can enjoy consistent performance each time they use it. Optimal for Light and Heavy Work with Excellent Workmanship. The VEVOR rotary table is ideal for both light and heavy work. It shows excellent workmanship in its design and construction. The solid build handles the demands of various milling tasks. No matter if you’re working on small projects or larger tasks, the table performs well. Its stability and durability make it versatile for different jobs. Users can depend on its accuracy and longevity no matter what task is at hand. This flexibility is one of its key benefits. So, it should be a good addition to any workshop. It’s easy to set up and pack ### Arrives Well-Packaged and Easy to Set Up. Setting it up is easy, thanks to logical assembly parts. Proper packaging ensures that every piece remains intact on arrival. The setup process is straightforward and requires minimal effort. Instructions are clear and simple to follow. With just a bit of time and effort, the rotary table is ready for use. This ease of setup makes it convenient, even for those new to milling. This is perfect for Hobbyists & Professionals Alike with Versatile Usage. It is a useful rotary table for both hobbyists and professionals. It has versatile functionality that meets various needs and projects. Hobbyists will find it perfect for personal projects, while professionals can depend on its consistent performance. The table is adaptable, accommodating different tasks and work styles. This versatility makes it an invaluable tool in any setting. You can count on it for different milling jobs. These flexible features ensure you get the most out of your investment. Maintains Precision Even on Budget, Providing the Best Value. The VEVOR rotary table provides precision without breaking the bank. It’s budget-friendly while ensuring high performance and accuracy. The value for the price is unmatched, making it an excellent choice for budget-conscious buyers. Precision in design permeates every detail, from the center bore to the reduction ratio. It maintains tight tolerances even in demanding conditions. This reliability is a testament to its quality, providing great value and accuracy on a budget. For Effective Operation, ### Minimal Backlash and Good Movement Range for Effective Operations #### Minimum Support & Great Movement. The VEVOR rotary table ensures efficient operations. The movement range is generous, catering to various setups and adjustments. It moves without noticeable hesitation or delay, ensuring smooth operations. Minimal backlash means more precise cuts and better overall performance. This allows for detailed and accurate work, critical for milling tasks. Good movement range further enhances its functionality, making it an efficient and effective piece of equipment. Specifications: – Length: 38.0 in, Width: 33.0 in, Height: 19.0 in. Sorry, our items are NOT available for pick-up. No additional information at this time. You might also like. VEVOR Grease Pump, 50:1 Pressure Ratio Air Operated Grease Pump with 13 ft High.

4 100MM Rotary Table Horizontal Vertical 4 Slots for Milling Machine Regular

4 100MM Rotary Table Horizontal Vertical 4 Slots for Milling Machine Regular. Chuck Diameter 4? (100 mm). Vertical Center Height 2-1/16? Approx. Hand Wheel can be set to zero. Hand Wheel graduated in 10 min divisions. Cali berated in 5 min increment around the rim. Can be used both Horizontally & Vertically.

Phase II Rotary Table 12 Diameter 4MT Horizontal / Vertical 221-312 Damaged

There are dents and scuff marks on the item from previous use. Please carefully review photos and ask any questions you may have prior to submitting an offer. Comes exactly as shown. Message us for a quote today! To get a quote please answer the following questions in this order. Will there be a loading dock or forklift.