Author: admin

Bosch GRL2000-40HVK Self Leveling Horizontal/Vertical Rotary Laser

Bosch GRL2000-40HVK Self Leveling Horizontal/Vertical Rotary Laser kit, condition is light use, once/twice, no real physical wear and tear, comes exactly as shown, includes everything you see in pictures, please see pictures for more details.. Please note: no correct size box to fit, will have to cut to fit..

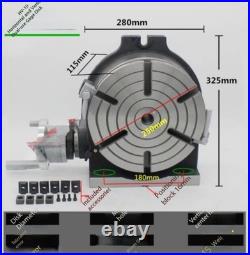

HV-8 Milling Machine Horizontal Indexing Table Rotary Table Vertical Dual-Use

4-inch diameter 110mm vertical and horizontal milling machine horizontal vertical turntable high precision indexing plate. Product name: Vertical and horizontal 4-inch disc diameter 110mm. Middle through hole: 16mm. Indexing error: 360° error 0.04°. Turbine worm: speed ratio 1:72. Vertical center 1027 height 85.5mm.

Vertical-Horizontal Indexing Table Rotary Work Table HV5 Milling Machine

Vertical and horizontal dual-use indexing table rotary table milling machine. Rotary table horizontal vertical indexing plate. Product Name:Horizontal dual-use indexing plate.

Grizzly G0757 9 x 39 2 HP Horizontal/Vertical Mill with Power Feed WILL SHIP

Grizzly G0757 Only 2-3 years old, runs great! Just do not use anymore. I might have some tooling I can part with too for an additional price. Also have a Grizzly GT1191 Rotary Table w/ DRO. Contact me if you want to make some sort of package deal. In it’s crate, this will probably weight 2100lbs. We’re in Ormond Beach, FL 32174.

Tsudakoma RNCM-251L Horizontal/Vertical CNC Rotary Table, Full Contouring, 1994

Great American Equipment Company. 10 TSUDAKOMA HORIZONTAL/VERTICAL CNC ROTARY TABLE. Model RNCM-251L, S/N 940088, New 1994 Stock# K14300. East end of Bins. This Horizontal or Vertical Mount CNC Rotary Table was Designed for Full Contour Milling or Indexing of Parts. The Table is Driven by a Fanuc Electric Servo Motor with Resolver Feed Back. For Work Holding it has a 9.84 Round T-Slotted Work Mounting Surface. Table was taken off a Vertical Machining Center with a Fanuc Drive Package. Will fit Most Other Machines with a Simple Change of the Servo Motor. Max Load Capacity, Vertical. Max Load Capacity, Horizontal. Distance Base to Center of Table (Vertical Mount). Distance Base to Top of Table (Horizontal Mount). CONDITION: Table Appears to be in Excellent Condition! We can load for free any weight item. We will help with trucking by using our nationwide network to get you the very best trucking rate. If there is an issue, you can deal directly with the transportation provider. Questions and Trucking Quotes. We are here to answer your questions and to help with a trucking quote. From Outside the US & Canada call (5137712111).

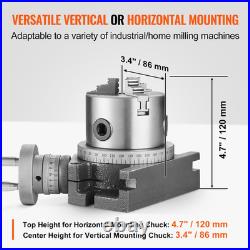

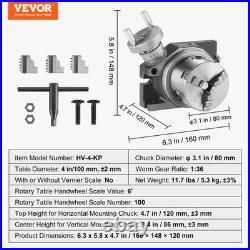

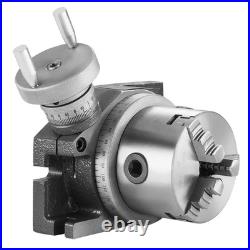

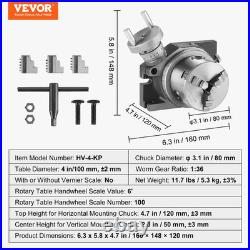

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools4-Inch Rotary Table for Milling Machine3-Jaw ChuckClear ScaleHorizontal & Vertical UseSuperior HardnessDual Handle DesignRotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ±3 mm, Rotary Table Handwheel Scale Value: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical Mounting Chuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or Without Vernier Scale: No, Chuck Diameter:? 3.1 in / 80 mm, Table Diameter: 4 in / 100 mm, ±2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm, Net Weight: 11.7 lbs / 5.3 kg ± 3%Specifications:- Length: 19.0 in, Width: 17.0 in, Height: 18.0 in. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools 4-Inch Rotary Table for Milling Machine 3-Jaw Chuck Clear Scale Horizontal & Vertical Use Superior Hardness Dual Handle Design Rotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ±3 mm, Rotary Table Handwheel Scale Value: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical Mounting Chuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or Without Vernier Scale: No, Chuck Diameter:? 3.1 in / 80 mm, Table Diameter: 4 in / 100 mm, ±2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm, Net Weight: 11.7 lbs / 5.3 kg ± 3% Specifications: – Length: 19.0 in, Width: 17.0 in, Height: 18.0 in. Sorry, our items are NOT available for pick-up. No additional information at this time. You might also like. 29 Inch Dance Bag with Garment Rack Rolling Duffle with Wheels for Travel Pink. Axe Throwing Game Plastic Bristle Target with 8 Throwing Axes Set Steel Frame. VEVOR Sparkling Water Maker, Soda Maker Machine for Home Carbonating, Seltzer Wa. Slushy Machine for Home Margarita Slush Maker 32oz Smoothie Frozen Drink Maker.

Rotary Table With 70 mm 4 Jaw Independent Chuck and back Plate-USA FULFILLED

Rotary Table With 70 mm 4 Jaw Independent Chuck and back Plate. A rotary table is used to rotate a workpiece precisely during machining, allowing for accurate creation of circular features, angles, and indexing tasks. A chuck is used to securely hold and grip a workpiece on a machine tool, ensuring it remains stable and aligned during operations like turning, drilling, or milling. Chuck 70 mm 4 Jaw Independent. Precision 70 mm 4-Jaw Independent Lathe Chuck. Compatible with M14 x 1 mm threading. 3/ 80 mm Rotary Table. Small low profile Rotary Table for Milling operation with Table Diameter – 3 Inches (80 mm) Vertical Height – 1-5/8 Inch. Gear Ratio – 36:1, which basically means that the 1 rotation of the handle shall rotate the table by 10 degrees. 1/4″ 4 T-Slots: 5/16″. Table scale is calibrated in 5 degree increment. Can be used both in horizontal & vertical position. 3/ 80 mm tilting. Low Profile Precision Mini Rotary Table 3 75mm is manufactured from Seasoned casting. Worm- Gear Ratio – 36:1, which basically means that the 1 rotation of the handle shall rotate the table by 10 degrees. Material :- Tool Steel & Casting. 4/ 100 mm Regular. Very High Quality 4 /100 mm Regular Rotary Table designed for smaller milling machines. Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position: 2-1/16 (50 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. 4/ 100 mm tilting. Horizontal & Vertical Rotary Table 4 Table height 66 mm in flat position. Table graduated 360 degrees in 5 degree divisions. Rotary Tables deliver precise, continuous rotating motion for scanning, assembly, testing and production. They are a convenient, accurate method of quickly positioning a payload. The tables use a rugged worm and gear drive design with a central rotating ball bearing.

Tsudakoma RNA-251R CNC Rotary Table 4 Axis

The Tsudakoma RNA-251R CNC Rotary Table is a high-quality workholding device designed for CNC machining. With the ability to operate in both horizontal and vertical positions, this rotary table offers versatility and precision for various manufacturing needs. The CNC operation ensures efficient and accurate workholding, making it an essential tool for metalworking and manufacturing businesses. The Tsudakoma brand is known for its reliability and durability, making this rotary table a trusted choice for professionals in the industry. Dimensions of the unit itself is 19″ wide x 11″ tall x almost 9 deep. Circumference of the rotary face is 10.