Vertical & Horizontal Milling Machine Rotary Table 360° for Indexing Drilling

Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table, one of the main accessories of the milling machine, is a precision work positioning device. This machine is widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis. Vertical & Horizontal Position. Tough Equipment & Tools, Pay Less. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, VEVOR is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Note: 100MM / 4 Milling Rotary Table without Centre Bore. Vertical & Horizontal Design. It can be mounted “flat, ” with the table rotating around a vertical axis, in the same plane as the cutter of a vertical milling machine. Or, mounted the rotary table on its end (or mount it “flat” on a 90° angle plate) so that it rotates about a horizontal axis. In this configuration, a tail stock can also be used, thus holding the workpiece between centers. HT200 casting has excellent casting performance, shock absorption performance as well as high strength heat resistance. It ensures the superior performance of the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The minimum scale can be accurate to seconds. All of these help you handle more complex and more precise tasks. Spindle end is applied accuracy bearing. Can be assured to keep very steady under load cutting. It’s not difficult for you to adjust the rotary table milling machine. What you should do is to adjust the handle to the position where you want because the precise scale is marked on the dial. Except for the rotary machine table, we also offer you four locating blocks or wrench and screws. The center can be corrected quickly and accurately by the Key guide block. Widely used in metalworking, enabling the operator to drill or cut work at exact intervals around a fixed axis. Great for circular cutting work, boring, spotfacing, and similar work. 150MM / 6 Milling Rotary Table. Clamping table diameter: 150mm / 6. Number of grooves: 4. Width of grooves: 11mm / 0.43. Circular Accuracy: 0.04. The parallelism of the mounting surface: 0.04. Transmission of the worm gear: 90/1. Basic dimension horizontal: 180 x 170mm / 7 x 6.7. Basic dimension vertical: 205 x 80mm / 8 x 3.15. Height: 80mm / 3.15. Weight without packaging: 11.1kg / 24.47lb. Worktable with scale: 360 °. 40kg / 88.18lb. 20kg / 44.09lb. 1 x Vertical and Horizontal Rotary Working Table. 150MM / 6 Milling Rotary Table With Dividing Plates. T-slot Diameter: 1/2inch (14mm). Table Dimension: 6inch (150mm). Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. 1 x Rotary Table. 3 x Dividing Plates. 1 x A Set of Accessory. 100MM / 4 Milling Rotary Table. Table Diameter: 4/100mm. Reduction Ratio: 1:36. Horizontal Height : 2.76/70mm. Net Weight: 33.07/15kg. 1 x Screw Set. 100MM / 4 Milling Rotary Table With Dividing Plates. T-slot Diameter: 1/2inch (12mm). Table Dimension: 4x3inch (100x80mm). 200MM / 8 Milling Rotary Table 3-Slot. Table Diameter: 8/200mm. Horizontal Height : 4.13/105mm. Vertical Height : 1.57/40mm. 200MM / 8 Milling Rotary Table 4-Slot. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. VERTICAL & HORIZONTAL POSITION? – Our rotary table with four slots is 4” / 6” / 8” (100mm / 150mm / 200mm) in diameter, it can be used in horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. FANTASTIC MATERIAL? – HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Adopted it as the material, our rotary milling table is durable, shock-absorbing, and heat-resistant. EXCELLENT PRECISION? – The rotary table for milling machine can be graduated 360 Degrees. Resetting dial and handwheel can be graduated in seconds. The enclosed design prevents the penetration of dirt and chips. CONVENIENT TO ADJUST? – The dial of the rotary table for mill is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. WIDE APPLICATION? – This mill rotary table is popular for its excellent performance, practical design, and high precision. They are widely used for circular cutting work, boring, spot facing, and similar work.

Horizontal Vertical Rotary Table 4/100mm 6/150mm 4-Slot With 3 Dividing Plates

VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6″/150 or 4″/100mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. Clear scale is more convenient for you to operate it. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Three dividing plate set(Plate’A’ – 15, 16, 17, 18, 19, 20 Plate’B’ – 21, 23, 27, 29, 31, 33 Plate’C’ – 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. 4/100mm 4-Slot Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate. T-slot Diameter: 1/2inch 12mm. Table Dimension: 4x3inch (100x80mm). Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. 1 x Rotary Table. 3 x Dividing Plates. 1 x A Set of Accessory. 6/150mm 4-Slot Rotary Table. T-slot Diameter: 1/2inch 14mm. Table Dimension: 6inch (150mm).

Rotary Table 6(150 mm) 4-Slot Horizontal Vertical Dividing Plates for Milling M

Rotary Table 6(150 mm)_4-Slot Horizontal Vertical Dividing Plates for Milling M. Rotary Table 6(150 mm)_4-Slot Horizontal Vertical Dividing Plates for Milling Machine. Experience Precision and Versatility with the Rotary Table 6(150 mm)_4-Slot Horizontal Vertical Dividing Plates! Upgrade your milling machine capabilities with the Rotary Table 6(150 mm)_4-Slot Horizontal Vertical Dividing Plates. This powerful accessory is designed to enhance your precision and productivity, allowing you to perform a wide range of milling operations with ease. Vertical & Horizontal Design. Plate’B’ – 21, 23, 27, 29, 31, 33. Model: 6 inch Rotary Table. Plate’C’ – 37, 39, 41, 43, 47, 49. Setting Position: Horizontal / Vertical. Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm. Table Dimension: 6 inch / 150 mm. Plate’A’ – 15, 16, 17, 18, 19, 20. T-slot Diameter: 1/2 inch / 14 mm. Item Weight: 40 lbs / 18.18 kg. Items must be in original condition and packaging. If you have any issues with your order, please let us know. We will make every effort to resolve any problems and ensure you are satisfied. We appreciate your business. Thank you again for choosing to shop with us! Antibacterial Liquid Hand Soap, Crisp Clean, 11.25 Fluid Ounce Bottle. 13 Black Quietset Oscillating Table Fan, 10Ft Air Circulation Power. Extra Virgin Olive Oil, Rich Taste, 16.9 Fl Oz. (8 Pack) Corned Beef Hash, 14 Oz Can. Rainbow Fuzzy Sticks, 100-Pack. Auto Repair Workbench, 7 Piece Tool Set, for Toddlers 3+. Add suggested items to your listings.

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Tables

A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. 360-Degree Graduation: The table is graduated a full 360 degrees, allowing for precise control and positioning of the workpiece. The clear markings ensure easy and accurate angle setting for all your milling tasks. Worm Gear Ratio: 1:36 The gear ratio means that one full rotation of the handle turns the table by 10 degrees, providing fine control over the movement and ensuring precision in every operation. Vertical Position Center Height: 2-1/16 (50 mm approx) The center height in the vertical position is 2-1/16 inches, which aligns perfectly with the smaller milling machine setups, offering versatility in workpiece positioning. Handwheel Graduations: The handwheel is graduated in divisions of 10 minutes, allowing for highly detailed adjustments. The scale can also be set to zero, making it easy to track and repeat your adjustments for consistent results. Mounting Flexibility: The Regular model can be mounted in both horizontal and vertical positions, enhancing its versatility for a wide range of applications. Whether you need flat or angled cuts, this rotary table can handle it with ease.

Haas Hrt-160 4th Axis Rotary Table 6 Diameter Gha-10

If it is not shown in the pictures it doesn’t come with the item i. Power cords, attachments, tooling, etc. Most listings at the end include a GH and then a number for example (GH119) OR (A19) it is an internal stock reference number and not part of the item’s description. Once clicked, this will show the number to call.

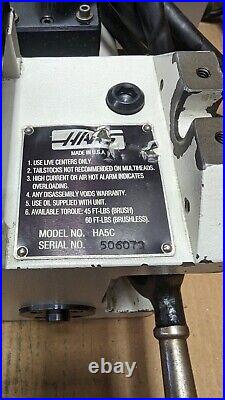

Haas HA5C Drive Programmable Rotary Table with Haas Servo Control

The Haas HA5C Drive Programmable Rotary Table with Haas Servo Control is a high-quality CNC machine accessory designed for precision machining. Made by the reputable brand Haas in the United States, this rotary table allows for horizontal and vertical setting positions, providing versatility for various machining needs. With its advanced technology and precise control, this product is ideal for businesses and industrial applications requiring accurate and efficient workholding and toolholding solutions. Full model designation: HAAS HA5C Rotary Indexer. Control type: Servo control (more precise than pneumatic models). Indexing resolution: 0.001° (standard for servo HA5C units). Maximum spindle speed: Typically 100 RPM. Mounting orientation options: Horizontal or vertical.

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Table-USA FULFILLED

Horizontal Vertical 4 Inch II 100 mm Rotary Milling Tables. A rotary table is a precision tool used predominantly in metalworking, particularly in machining operations like milling and drilling. Its primary function lies in enabling machining at precise angular intervals around a fixed point, commonly referred to as indexing. This capability facilitates the creation of intricate geometries, circular features, and multi-sided machining without the need for manual repositioning of the workpiece. By mounting the workpiece on the rotary table and rotating it, machinists can execute complex operations such as gear cutting, spiral grooving, and helical cuts with high precision. Additionally, rotary tables are essential for tasks requiring circular or arc-shaped machining, offering versatility and efficiency in manufacturing processes. Transform your machining capabilities with our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Engineered for precision and versatility, these rotary tables are designed to elevate your machining projects to new heights. Dual functionality: Can be used horizontally or vertically to accommodate a wide range of machining tasks. Generous 4 inch (100 mm) diameter provides ample space for various workpieces. Smooth rotary motion ensures precise positioning and milling operations. Sturdy construction for durability and long-lasting performance. Compatible with both horizontal and vertical milling machines, enhancing flexibility in your workshop. Precision-machined for exceptional accuracy, delivering reliable results with every use. Whether you’re performing intricate machining tasks or tackling larger projects, our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables deliver the precision and versatility you need for outstanding results. Upgrade your machining capabilities with the precision and versatility of our Horizontal Vertical 4 Inch (100 mm) Rotary Milling Tables. Elevate your workshop today!

Genuine Haas SC01M Servo Controller, 4th Axis Rotary 17 Pin Connector TESTED

This is a genuine Haas SC01M Servo Control for a 4th axis. It is used but in good usable condition. It works great and came off a running machine. The control itself is in great shape and looks to have very little usage on it. Powers up and controls our HRT160 just fine. Comes as shown with cords shown.