table

100mm /4Rotary Table Horizontal & Vertical + self centering Chuck 3 Jaws 80mm

4100mm Rotary Table Horizontal Vertical + 80mm 3 Jaw self centering Chuck. Rotary Table 4/100mm. Chuck Diameter 4? (100 mm). Vertical Center Height 2-1/16? Approx. Hand Wheel can be set to zero. Hand Wheel graduated in 10 min divisions. Cali berated in 5 min increment around the rim. Can be used both Horizontally & Vertically. 80mm 3 Jaw self centering Chuck. Chuck Size:- 80mm. 2 Kgs / 4.4 Lbs. Suitable For:- 4/100 MM Rotary Ta. PROUDLY MADE IN INDIA. ? RAHISHTOOLS comprises of a dedicated and skilled team of engineers with an aim of providing you tools of highest indian industrial standards. Situated at the industrial hub of. We specialize in providing complete tooling solutions. Our Motto : Right Quality. We ensure the product reaches you at the earliest. We are looking forward to your positive reviews and to build a long term relationship.

4 Inch 100mm Rotary Table Horizontal Vertical 65mm 3 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 65mm 3 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

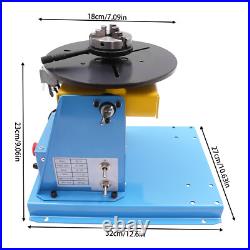

Modern Rotary Welding Positioner Turntable Table 10kg(Horizontal)/5kg(Vertical)

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 700;font-size: 23px}. Title:after{content:’HOT SALE';color: #ffffff}. Cs-list>li:nth-child(n+10){display:none}. Title{margin:0;font-weight: 700;font-size: 23px}. Title:after{content:’You may like';color: #FFFFFF}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off';font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid=”387461906808″]. Title:aftercontent:’Rotary Welding Positioner Turntable Table 110V 2.5\\.

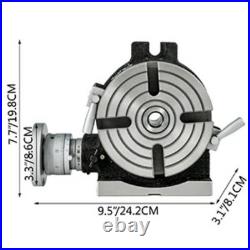

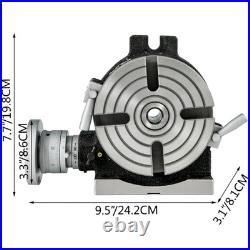

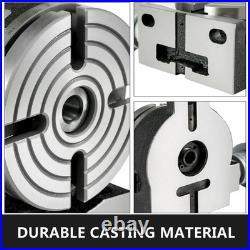

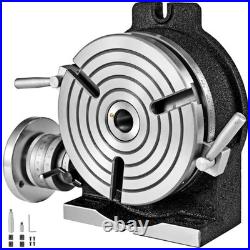

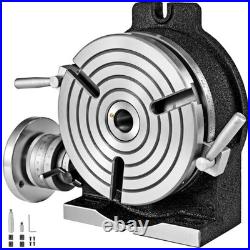

Rotary Table MT-2 4/6inch 4-Slot Horizontal Vertical Dividing Plates for Milling

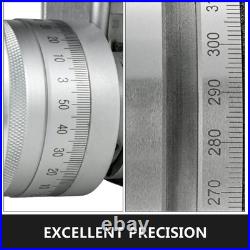

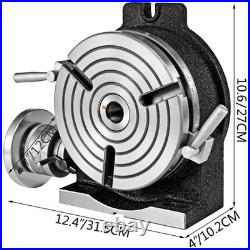

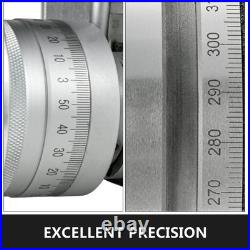

6/150mm Rotary Table 4-Slot Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. Clear scale is more convenient for you to operate it. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Three dividing plate set(Plate’A’ – 15, 16, 17, 18, 19, 20 Plate’B’ – 21, 23, 27, 29, 31, 33 Plate’C’ – 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Model: 6 inch Rotary Table. T-slot Diameter: 1/2 inch / 14 mm. Table Dimension: 6 inch / 150 mm. Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. Setting Position: Horizontal / Vertical. Item Weight: 40 lbs / 18.18 kg. Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm. 1 x Rotary Table. 3 x Dividing Plates. 1 x A Set of Accessories. Model: 4 inch Rotary Table. T-slot Diameter: 1/2 inch / 12 mm. Table Dimension: 4x3inch (100x80mm). VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs.

Rotary Table MT-2 4inch/100mm 6inch 4Slot Horizontal Vertical Dividing Plate

Dxm-rm-top{font-size:13px;max-width: 100vw;}. Dxm-rm-top ul{margin:0;padding:0}. Dxm-rm-top a{text-decoration:none}. Dxm-rm-top ul{list-style-type:none}. Dxm-rm-head{overflow:hidden;position:relative;padding:6px 12px;width:100vm;min-height: 20px;}. Dxm-rm-head-title{vertical-align:middle;max-width:calc(100% – 75pt)}. Dxm-rm-body{margin:0 0 0 -20px}. Dxm-rm-body:after {display: block;clear: both;height: 0;content: “\0020″}. Dxm-rm-body li{position:relative;float:left;display:inline-block;box-sizing:border-box;padding:10px 0 10px 20px;width:16.66%}. Dxm-rm-body li a{display:block;padding:5px;font-size:13px;border:1px solid #fff;}. Dxm-rm-body lipadding-left:20px;width:20%! Dxm-rm-body lipadding-left:18px;width:33.33%! Dxm-rm-body lipadding-left:15px;width:50%! Dxm-rm-body-col6 li{position:relative;float:left;display:inline-block;box-sizing:border-box;width:16.66%}. Dxm-rm-body-col7 li{padding-left:18px;width:14.28%}. Dxm-rm-body-col8 li{padding-left:1pc;width:12.5%}. Dxm-rm-body-col9 li{padding-left:15px;width:11.11%}. Dxm-rm-body-col10 li{padding-left:14px;width:10%}. Dxm-rm-body-cover:after{display:block;padding-top:100%;background-position:center;background-size:contain;background-repeat:no-repeat;content:”}. Dxm-rm-body-title:after{display:block;display:-webkit-box;overflow:hidden;height:2.8em;white-space:normal;font-size:14px;line-height:1.4em;-webkit-line-clamp:2;-webkit-box-orient:vertical;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Dxm-rm-body-attributte{overflow:hidden;height:20px}. Dxm-rm-body-mrsp{margin-left:3px;color:#a0a3a6;text-decoration:line-through;font-size:9pt} /! Content: “you may like”;! Dxm-rm-body > li:nth-child(n+7)! Content: “Portable Pet Dog Pooper Scooper Poper Scooper Poper Scooper Poper Scooper Poper Scooper Plastic Poop Scoop Picker Excreta Cleaner Tool”;! Dxm-rm-body li:nth-child(n+11){display: none;}. Dxm-rm-body-title:after color: #333333; content:?? VEVOR 30W Portable Fiber Laser Marking Machine Metal Engraver Lightburn 6\\.

Rotary Table 8 Inch/200 MM Horizontal Vertical 3MT Drilling Machines 3/ 4-Slot

Dxm-rm-top{font-size:13px;max-width: 100vw;}. Dxm-rm-top ul{margin:0;padding:0}. Dxm-rm-top a{text-decoration:none}. Dxm-rm-top ul{list-style-type:none}. Dxm-rm-head{overflow:hidden;position:relative;padding:6px 12px;width:100vm;min-height: 20px;}. Dxm-rm-head-title{vertical-align:middle;max-width:calc(100% – 75pt)}. Dxm-rm-body{margin:0 0 0 -20px}. Dxm-rm-body:after {display: block;clear: both;height: 0;content: “\0020″}. Dxm-rm-body li{position:relative;float:left;display:inline-block;box-sizing:border-box;padding:10px 0 10px 20px;width:16.66%}. Dxm-rm-body li a{display:block;padding:5px;font-size:13px;border:1px solid #fff;}. Dxm-rm-body lipadding-left:20px;width:20%! Dxm-rm-body lipadding-left:18px;width:33.33%! Dxm-rm-body lipadding-left:15px;width:50%! Dxm-rm-body-col6 li{position:relative;float:left;display:inline-block;box-sizing:border-box;width:16.66%}. Dxm-rm-body-col7 li{padding-left:18px;width:14.28%}. Dxm-rm-body-col8 li{padding-left:1pc;width:12.5%}. Dxm-rm-body-col9 li{padding-left:15px;width:11.11%}. Dxm-rm-body-col10 li{padding-left:14px;width:10%}. Dxm-rm-body-cover:after{display:block;padding-top:100%;background-position:center;background-size:contain;background-repeat:no-repeat;content:”}. Dxm-rm-body-title:after{display:block;display:-webkit-box;overflow:hidden;height:2.8em;white-space:normal;font-size:14px;line-height:1.4em;-webkit-line-clamp:2;-webkit-box-orient:vertical;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Dxm-rm-body-attributte{overflow:hidden;height:20px}. Dxm-rm-body-mrsp{margin-left:3px;color:#a0a3a6;text-decoration:line-through;font-size:9pt} /! Content: “you may like”;! Dxm-rm-body > li:nth-child(n+7)! Content: “Portable Pet Dog Pooper Scooper Poper Scooper Poper Scooper Poper Scooper Poper Scooper Plastic Poop Scoop Picker Excreta Cleaner Tool”;! Dxm-rm-body li:nth-child(n+11){display: none;}. Dxm-rm-body-title:after {display: none; color: #333333; content: “Hot Dividing Head Precision BS-4in/5in/6in 3-Jaw Indexing Head Tailstock Chuck”;}. Dxm-rm-body-price:after {content: “USD 259.99″;}. Dxm-rm-body-title:after display: none; color: #333333; content: Rotary Tables 6\\.

4 Inch 100mm Rotary Table Horizontal Vertical 70mm 4 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 70mm 4 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Independent Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

4 Inch 100mm Rotary Table Horizontal Vertical 50mm 3 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 50mm 3 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Rotary Table 4 4-Slot + 80mm Backplate + 70mm 4 Jaw Independent Chuck + Vise

Rotary Table 4 4-Slot + 80mm Backplate + 70mm 4 Jaw Independent Chuck + Vise. Upgrade your machining setup with this Rotary Table Kit designed for precision and versatility. Featuring a 4″ Plain 4-Slot Rotary Table, 80mm Backplate, 70mm 4-Jaw Independent Chuck (IJ), M6 14-Piece Clamping Kit, and a 4″ Round Vise, this set is ideal for both professionals and hobby machinists. Rotary Table: 4 Plain with 4-Slot design for stability. Backplate: 80mm, precision-fit for included chuck. Chuck: 70mm 4-Jaw Independent (IJ) – perfect for irregular and asymmetrical workpieces. Clamping Kit: M6, 14-piece set for flexible and secure setups. Vise: 4 Round, strong and accurate for precise positioning. Independent 4-jaw chuck for maximum versatility in clamping. Precision-ground rotary table for smooth, accurate indexing. Durable steel construction ensures long service life. Suitable for circular machining, drilling, boring, and milling operations. Works with milling machines, mini lathes, and drill presses. ? Package Contains: 1 × Rotary Table 4″ (Plain, 4-Slot) 1 × 80mm Backplate 1 × 70mm 4-Jaw Independent Chuck (IJ) 1 × M6 Clamping Kit (14 Pcs) 1 × 4″ Round Vise. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.