chuck

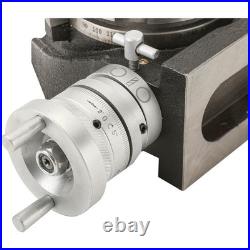

Mill Rotary Table 100mm 4 Inch Horizontal Vertical with 3-Jaw Chuck

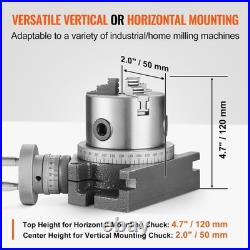

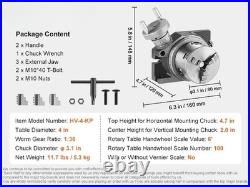

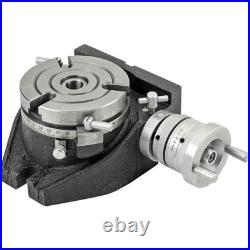

1.4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter: 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (3 mm), and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. 4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn.

4 Inch 100mm Rotary Table Horizontal Vertical 65mm 3 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 65mm 3 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

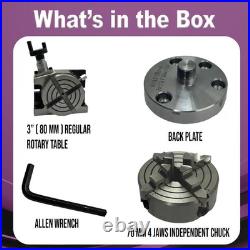

MachEl 3 (80mm) Rotary Table with 4 Slots, 70mm 4-Jaw Chuck & Back Plate

Enhanced 3 Inches (80mm) Rotary Table with 4 Slots with 70mm 4-Jaw Independent Chuck and Back Plate. ? MachEl 3 (80mm) Rotary Table with 4 slots and 70mm 4-Jaw Independent Chuck. ?? Versatile for horizontal and vertical clamping in machining operations. ? Calibrated 0-360 degree scale with 36-1 ratio for precise positioning. ? Enables accurate drilling or cutting at fixed intervals around a central axis. ? Low-profile design at 1-5/8, ensuring stability and flexibility. ? Includes 65mm 3-Jaw Self-Centering Chuck with mounting back plate and fixing tee nuts. ? Suitable for various milling machine sizes, with an overall height of 52-53mm. Introducing the MachEl Enhanced 3 (80mm) Rotary Table featuring 4 slots, paired with a 70mm 4-Jaw Independent Chuck and Back Plate. This versatile unit is designed for precision in machining operations, whether horizontal or vertical clamping. With a compact profile of just 1-5/8, it offers both flexibility and stability for various workshop tasks. The rotary table boasts a calibrated scale from 0 to 360 degrees with a 36-1 ratio, ensuring precise positioning with every handle turn. This feature enables users to accurately drill or cut workpieces at specific intervals around a fixed axis, enhancing efficiency and accuracy in milling operations. Included in this assembly is a 65mm 3-Jaw Self-Centering Chuck complete with a mounting back plate and fixing tee nuts, facilitating easy and secure attachment to the rotary table. The overall height of the setup is approximately 52-53mm, making it suitable for a range of milling machine sizes. Ideal for hobbyists and professionals alike, this MachEl rotary table and chuck combination is engineered to deliver reliability, precision, and ease of use in machining applications.

Milling Rotary Table 4”/100mm Horizontal Vertical with 3-Jaw Chuck Indexing

4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn. 4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our? 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter:? 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”- 0.98” / 2-25 mm, Internal Clamping Range: 0.98”- 2.76”/ 25-70 mm. It includes an external jaw and external clamping range of 0.87”-2.76” / 22-70 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (±3 mm), and when mounted vertically, the chuck center height is 3.4” / 86 mm (±3 mm). Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations.

4 Inch 100mm Rotary Table Horizontal Vertical 65mm 4 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 65mm 4 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

4 Inch 100mm Rotary Table Horizontal Vertical 70mm 4 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 70mm 4 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Independent Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

T1190 4-3/8 Rotary Table with Tailstock and Chuck

A precision rotary table with a chuck and tailstock. A rotary table allows drilling or cutting at exact intervals around vertical and horizontal axes. The T1190 4-3/8 Rotary Table can be used in either the horizontal or vertical position for a variety of milling applications. These different operations include milling eccentric features, cutting arcs, create large diameter holes, and circular profiles. Control is very accurate and precise thanks to the direct mount self-locating 3-jaw chuck, 4° table movement per handle rotation, and 20 second vernier scale. The tailstock supports larger workpieces when the rotary table is in the vertical position, while maintaining a high level of accuracy. The T1190 manual was written by our U. Based Technical Documentation Department and is packed with useful information. The complete and easy-to-read manual makes it easier to assemble and maintain your rotary table. Worm gear ratio: 72:1. Table diameter: 4.375. Table height: 3.82. Can be used in horizontal or vertical position. 4° movement per handle rotation. 5 second vernier scale.

HV4 Rotary Table With 65mm 3 Jaw Self Centering Chuck Lathe Back plate Tee Nut

4 ROTARY TABLE 4 SLOTS + 65mm 3 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

10 H/V Rotary Table With 10 3 Jaw Front Mount Self Centering Chuck

10″ H/V Rotary Table With 10″ 3 Jaw Front Mount Self Centering Chuck. There is center align pin come with Shars Brand rotary table. Located by chuck’s jaws, high TIR. The tools’s TIR reaches Chuck’s TIR 0.003 and rotary table’s TIR when you turn the handle to divide degree, because the center of tools and the center of chuck are coincide. There is no center align pin with other’s brand rotary table, only come with screws. The tools’ TIR can’t be guaranteed when you turn the handle to divide degree, because the center of tools and the center of chuck are’t coincide. The rotary table has no TIR, so only low TIR tools can be machined. Table diameter: 9.84. Horizontal O/A Height: 4.53. Center height vertical position: 6.49. Overall height in vertical position: 12.79′. Overall width (not including handle) in vertical position: 11.02′. Mounting table bolt width: 0.63′. T-slot width: 0.55′. Center taper: Morse Taper 3. Without coolant pathway on rotary table base to catch the coolant. 10 second vernier reading. Gear drive immersed in oil. Extra deep coolant channel. Dual positive action locks. Maximum individual spacing error 4″ table 120″, 6″ table 80″, 8, 10, 12, 16″ tables 60″. 4 table utilizes low profile locks for added workspace. Gear ratio: 4″ table is 72:1; 6-16″ tables are 90:1. Flatness of clamping service-concave. Concentricity of center bore. Parallelism of clamping surface to angle face. Squareness of angle surface to clamping surface. Squareness of clamping surface to center slot. Mounting: Front Mounting & Plain back. Center hole: 3.15. Bolt Circle Diameter: 8.898. Semi-steel chuck body made from high quality cast iron. Three pinion design with each pinion ground and hardened to HRC 43. Two piece jaw design with a master jaw and a top reversible jaw in American Standard tongue and groove specification. Both side of jaw teeth and guides are ground and hardened to HRC 58-62. Each set of jaws are serialized in their own set. A serialized set of jaws are then finished, ground, and lapped on their designated chuck body which will be the same chuck body on the final assembly to achieve a greater accuracy. Before assembling the jaw to its designated chuck body, the jaw’s finish machining are performed on a closed tolerance state of the art CNC machine from Japan. Scroll plate’s thread flank are ground on both side to achieve a tighter contact with the master jaw. Each chuck has gone through rigorous accuracy and repeatability inspection with clamping and jamming multiple random testing rods or rings. Accuracy is maintained for the entire clamping range.