horizontal

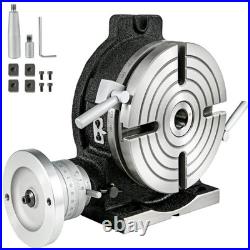

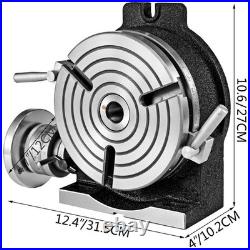

Global F2-6 Horizontal & Vertical Rotary Table 6 1/2 ($800 Obo)

GLOBAL F2-6 HORIZONTAL & VERTICAL ROTARY TABLE. CENTER HEIGHT 130 MM. Local deliveries available, simply message us before purchasing so we can properly adjust the listing for you. UPS 3 Day Select. UPS 2 Day Air. The item you receive may not be the exact one pictured when multiple items are listed. We are open Monday-Friday 8am-4pm CST. If you have old, used, or new surplus equipment to liquidate please let us know. Thank you for your business!

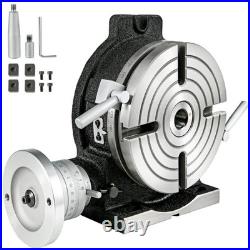

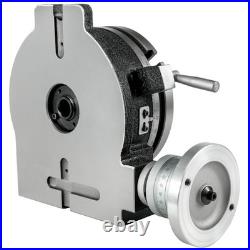

8in Precision Horizontal Vertical Rotary Table 3MT Milling Drilling Boring

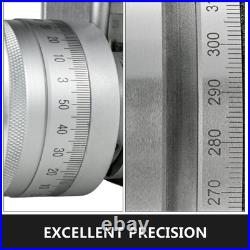

Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Unbranded is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Unbranded is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Unbranded has occupied markets of more than 200 countries with 10 million plus global members. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table.

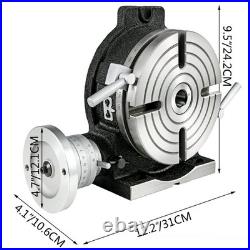

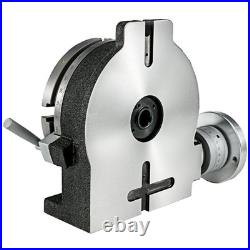

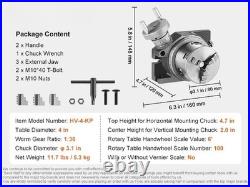

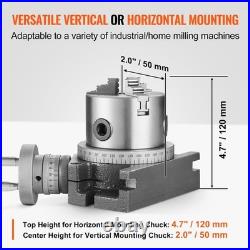

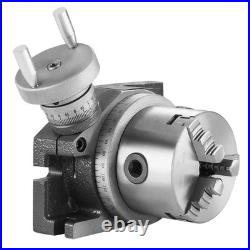

100mm 4 in Horizontal Vertical Rotary Table for Machining and Milling

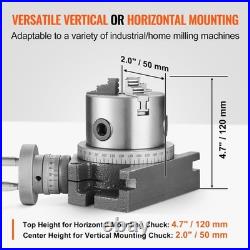

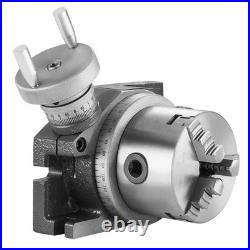

1.4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter: 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (3 mm), and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. 4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn.

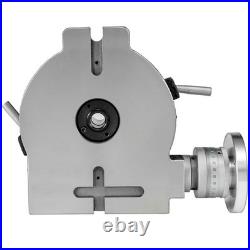

8in Horizontal Vertical 3MT Precision Rotary Table Milling Vernier Drilling

Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Unbranded is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Unbranded is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Unbranded has occupied markets of more than 200 countries with 10 million plus global members. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table.

Precision Horizontal Vertical 8in Rotary Table 3MT Vernier Drilling

Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Unbranded is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Unbranded is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Unbranded has occupied markets of more than 200 countries with 10 million plus global members. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table.

Horizontal Vertical 8in Precision Rotary Table 3MT Drilling Milling

Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Unbranded is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Unbranded is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Unbranded has occupied markets of more than 200 countries with 10 million plus global members. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table.

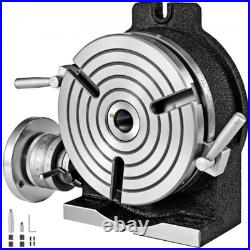

VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary

VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary Table for Milling Machine MT-3 Rotary Table for Milling 360 Degrees Precision Rotary TableVertical & Horizontal DesignHT200 CastingExcellent PrecisionEasy to AdjustFree Wrench & ScrewVarious ApplicationVertical Height : 1.57″/40mm, Horizontal Height : 4.13″/105mm, Material: HT200 Casting, Table Diameter: 8/200mm, Reduction ratio: 1:90, Center Bore: MT-3 Multiple Application: With free wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Best choice of motor parts. VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary Table for Milling Machine MT-3 Rotary Table for Milling 360 Degrees Precision Rotary Table. VEVOR Rotary Table 8 Inch/200 MM Horizontal Vertical Rotary Table 3-Slot Rotary Table for Milling Machine MT-3 Rotary Table for Milling 360 Degrees Precision Rotary Table Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Free Wrench & Screw Various Application Vertical Height : 1.57″/40mm, Horizontal Height : 4.13″/105mm, Material: HT200 Casting, Table Diameter: 8/200mm, Reduction ratio: 1:90, Center Bore: MT-3. Multiple Application: With free wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: The precision rotary table’ indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. 8″ Vertical & Horizontal Design: Our rotary table for milling machine is 8″ / 200 mm with 3 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Payments are expected within 4 days after the order is confirmed. We use multiple fulfilment warehouse around the United States. We shall not be held responsible for any wrong or undeliverable addresses. Note: For your best shopping experience in our store and saving your time. Because “return request” can’t help you to solve the problem efficiently, it may takes a little longer time for u to get a reply due to we check with our “return request” every 2 days. You will receive helpful and practical solution through the communication between us. If you need return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Then get a unique address for return. · We care about all of our customers, and will always do our best to solve any problem. Please NEVER leave Negative or Neutral feedback before connecting with us. · We will reply to all your questions within 24 hours. 2.5Universal Aluminum Intercooler Pipe Kit Black Hose Clamp. Stainless Steel Performance Exhaust Headers For Ford Merc L6 144/170/200/250 CID. VEVOR Forever Flowers, 50 Preserved Roses in a Heart Shape Box, Eternal Flowers Im. VEVOR Forever Flowers, 27 Preserved Roses in a Box, Eternal Flowers Immortal Bouqu. VEVOR Forever Flowers, 27 Preserved Roses in a Heart Shape Box, Eternal Flowers Im.

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling BoringVertical & Horizontal DesignHT200 CastingExcellent PrecisionEasy to AdjustWrench & ScrewVarious ApplicationVertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3 Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to us.. Best choice of motor parts. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Payments are expected within 4 days after the order is confirmed. We use multiple fulfilment warehouse around the United States. We shall not be held responsible for any wrong or undeliverable addresses. Note: For your best shopping experience in our store and saving your time. Because “return request” can’t help you to solve the problem efficiently, it may takes a little longer time for u to get a reply due to we check with our “return request” every 2 days. You will receive helpful and practical solution through the communication between us. If you need return, please check twice to confirm the item not work and contact our customer service representative, let us know the detailed problem and send us some pictures for confirmation. Then get a unique address for return. · We care about all of our customers, and will always do our best to solve any problem. Please NEVER leave Negative or Neutral feedback before connecting with us. · We will reply to all your questions within 24 hours. Stainless Steel Performance Exhaust Headers For Ford Merc L6 144/170/200/250 CID. 2.5Universal Aluminum Intercooler Pipe Kit Black Hose Clamp. VEVOR Forever Flowers, 27 Preserved Roses in a Box, Eternal Flowers Immortal Bouqu. VEVOR Forever Flowers, 27 Preserved Roses in a Heart Shape Box, Eternal Flowers Im. VEVOR Forever Flowers, 50 Preserved Roses in a Heart Shape Box, Eternal Flowers Im.

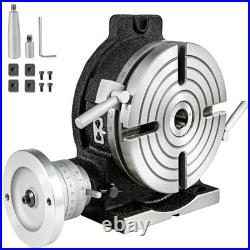

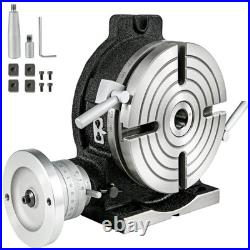

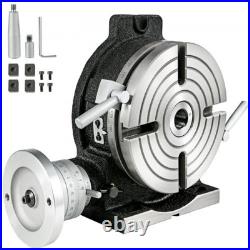

Milling Rotary Table 4”/ 100 Mm, Horizontal Vertical Model with 3-Jaw Chuck

4-Inch Rotary Table for Milling Machine. Precision and Versatility for Complex Milling Tasks. Our 4-inch (100 mm) rotary table is tailored for small milling machines, providing the control and accuracy essential for intricate dividing cuts and curved surface machining. Equipped with both horizontal and vertical functionality, it elevates your milling capabilities with ease and precision. Effortless Workpiece Positioning High-Precision Machining Horizontal & Vertical Operation Enhanced Durability for Lasting Use Easy Setup with T-Bolt Compatibility. 4-Inch Milling Machine Rotary Table:Enhance your milling accuracy with this compact 4 rotary table. Designed for rotation, indexing, and secure clamping of wood and metal, it’s perfect for curved surface machining and elongated hole processing. Firm Workpiece Clamping:The rotary table includes an 80 mm 3-jaw chuck with serrated jaws for secure gripping. Accommodates clamping ranges up to 2.5 (63 mm) for versatile machining of smaller components. Precision at Your Fingertips:The handwheel, marked with a 1:36 gear ratio, rotates the table in 10-degree increments. With 100 scale divisions and a clear 360° table mark, this table delivers exact positioning and control. Horizontal & Vertical Mounting Options:Ideal for diverse setups, our rotary table supports horizontal mounting with a 4.7 height or vertical mounting at 2. Bottom slots allow quick, stable attachment to compatible milling machines. HT250 Cast Iron Durability:Constructed from high-hardness HT250 cast iron, this rotary table resists wear and deformation, providing consistent performance under high load and high-speed operations. Comprehensive 4-Inch Rotary Table. Our 4 (100 mm) rotary table is the perfect addition to small milling machines, enhancing capabilities in rotating, indexing, and clamping workpieces with absolute precision. Ideal for specialized milling projects. Precise 3-Jaw Chuck Design. Featuring a versatile 3-jaw chuck with both internal and external jaws, our rotary table accommodates various workpiece sizes and ensures stable clamping. Quick adjustments with the T-shaped chuck wrench make setup hassle-free. Clear Graduated Scale for Accuracy. Engineered for precision, our rotary table comes with a 1:36 worm gear ratio and an easy-to-read scale, allowing for controlled rotations. A lock mechanism provides stability during complex machining tasks. Optimized for both horizontal and vertical configurations, this rotary table adapts to different milling setups. The positioning slot ensures stability, whether the table is set horizontally or vertically. Exceptional Hardness & Durability. Made from HT250 cast iron, this table provides wear resistance and high hardness, ensuring reliable performance in heavy-duty applications. Built for extended use in demanding machining environments. Convenient Dual Handle Design. With one long and one short handle, our rotary table’s handwheel is designed for intuitive and smooth operation, facilitating seamless 360° rotations for detailed precision work. Table Diameter: 4 in / 100 mm ± 2 mm Horizontal Mount Chuck Top Height: 4.7 in / 120 mm ± 3 mm Vertical Mount Chuck Center Height: 2 in / 50 mm Chuck Diameter:? 3.1 in / 80 mm Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 × 148 × 120 mm Net Weight: 11.7 lbs / 5.3 kg ± 3% Worm Gear Ratio: 1:36 Handwheel Scale Number: 100 Handwheel Scale Value: 6′ Model: HV-4-KP/li>. 1 x Chuck Wrench 2 x Handle 3 x External Jaw 2 x M10 Nuts 2 x M1040 T-Bolt 1 x User Manual.

4in/100mm 3.1in/80mm 3-Jaw Chuck Rotary Table, Horizontal & Vertical Use

1.4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter: 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (3 mm), and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. 4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn.