inch

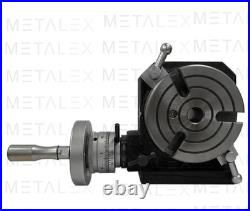

4 Inch 100mm Rotary Table Horizontal Vertical 65mm 4 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 65mm 4 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Self Centering Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

4 Inch 100mm Rotary Table Horizontal Vertical 70mm 4 Jaw Mini Small Lathe Chuck

4 ROTARY TABLE 4 SLOTS + 70mm 4 JAW LATHE CHUCK + BACKPLATE + TEE-NUTS. Vertical Center Height : 52mm. Can be used Horizontally as well as Vertically. Hand Wheel graduated in 10 min divisions. Hand Wheel can be set to zero. Calibrated in 5 min increment around the rim. Worm Gear Ratio – 36 : 1. Jaws : Independent Jaws Reversible Style. Jaw Type : Reversible Mounting Thread : M14x1. Body is made from graded cast iron. Jaws are made from quality tool steel, hardened & ground. Backplate Threaded – M14x1 Male Thread. Made for 3″ & 4″ rotary tables having 3 slots as well as 4 slots Solid Single Piece Steel Construction. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Rotary Table 4 Inch 110mm 3 Slots MODEL HV4 With Center Bore MT2 USA STOCKIST

HV4 MODEL – 4 /110mm ROTARY TABLE 3 SLOTS – HORIZONTAL / VERTICAL (HEAVY DUTY). Vertical Center Height : 80mm 3-9/64 Approx. Can be used Horizontally as well as Vertically. Vernier scale calibrated to 10 seconds. Hand Wheel can be set to zero. Worm Gear Ratio – 90 : 1 Table Center Bore – MT2. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machi

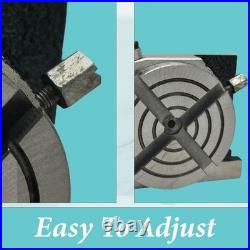

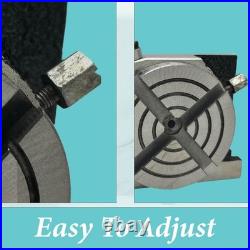

Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. VEVOR Rotary Table 8 Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3.

Rotary Table 3 inch 75mm Horizontal & Vertical Model- Milling Machine 4 sl

The Regular Rotary Table – ART Series is designed for machinists who demand precision, strength, and versatility. Built from high-grade cast iron and finished with ground surfaces, these rotary tables ensure smooth and accurate machining operations. Available in 3-inch (75 mm) and 4-inch (100 mm) sizes, the ART Series covers both Regular Rotary Tables and HV (Horizontal & Vertical) models, with 3-slot and 4-slot options. Perfect for milling, drilling, cutting arcs, indexing, and other precision engineering applications. Precision Engineered (ART Series): Designed for accuracy with ground surfaces and tight machining tolerances. Regular Rotary Table Design: Reliable performance for daily workshop and industrial milling needs. Multiple Sizes & Variants: Available in 3″ (75 mm) & 4″ (100 mm) sizes with 3-slot and 4-slot options. HV Model Option: Switch easily between horizontal and vertical machining setups with HV models. Durable Construction: Manufactured from premium cast iron for long life and stability. Wide Applications: Perfect for drilling, cutting arcs, indexing, angle setting, and other milling tasks.

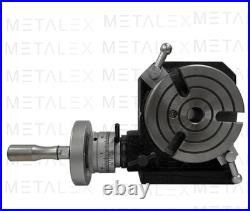

Rotary Table 4 Inch 110mm 3 Slots MODEL HV4 With Center Bore MT2 USA STOCKIST

HV4 MODEL – 4 /110mm ROTARY TABLE 3 SLOTS – HORIZONTAL / VERTICAL (HEAVY DUTY). Vertical Center Height : 80mm 3-9/64 Approx. Can be used Horizontally as well as Vertically. Vernier scale calibrated to 10 seconds. Hand Wheel can be set to zero. Worm Gear Ratio – 90 : 1 Table Center Bore – MT2. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Rotary Table 4 Inch 110mm 4 Slots MODEL HV4 With Center Bore MT2 USA STOCKIST

HV4 MODEL – 4 /110mm ROTARY TABLE 4 SLOTS – HORIZONTAL / VERTICAL (HEAVY DUTY). Vertical Center Height : 80mm 3-9/64 Approx. Can be used Horizontally as well as Vertically. Vernier scale calibrated to 10 seconds. Hand Wheel can be set to zero. Worm Gear Ratio – 90 : 1 Table Center Bore – MT2. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Rotary Table 3 Inch 75Mm Horizontal & Vertical Model- Milling Machine 4 Slots

Rotary Table 3 Inch – 75Mm Horizontal & Vertical Model- Milling Machine 4 Slots (I). Quality Low Profile Rotary Table diameter 80 mm (3Inches). Table is graduated 360 Degrees. Worm Gear Ratio -1:36, which means that the 1 handle rotation shall turn the table by 10 Degrees. Center Height in vertical position without chuck: 2-5/8 (66 mm approx). Hand wheel is graduated in divisions of 10 min & can be set to zero. Can be mounted both in Horizontal & vertical position. Table diameter 80 mm (3) Table is graduated 360 Degrees. Center Height in vertical position without chuck: 2-5/8 (66 mm approx) Hand wheel is graduated in divisions of 10 min & can be set to zero. 3 inch – 75mm. CASTE IRON & TOOL STEEL. 7.99 x 6.02 x 3.46 inches. We reserve the right to cancel any order for any reason at any time. We are not responsible for undeliverable addresses. Your feedback very important to us, after you get your package and you are. Satisfied with our service. If you have any problem with your order / any questions please before leave any type of feedback. Thank you for shopping at our store.

Rotary Table 3 inch 75mm Horizontal & Vertical Model- Milling Machine 4 sl

The Regular Rotary Table – ART Series is designed for machinists who demand precision, strength, and versatility. Built from high-grade cast iron and finished with ground surfaces, these rotary tables ensure smooth and accurate machining operations. Available in 3-inch (75 mm) and 4-inch (100 mm) sizes, the ART Series covers both Regular Rotary Tables and HV (Horizontal & Vertical) models, with 3-slot and 4-slot options. Perfect for milling, drilling, cutting arcs, indexing, and other precision engineering applications. Precision Engineered (ART Series): Designed for accuracy with ground surfaces and tight machining tolerances. Regular Rotary Table Design: Reliable performance for daily workshop and industrial milling needs. Multiple Sizes & Variants: Available in 3″ (75 mm) & 4″ (100 mm) sizes with 3-slot and 4-slot options. HV Model Option: Switch easily between horizontal and vertical machining setups with HV models. Durable Construction: Manufactured from premium cast iron for long life and stability. Wide Applications: Perfect for drilling, cutting arcs, indexing, angle setting, and other milling tasks.

Precision Rotary Table 6 Inch Horizontal Vertical Indexing Dividing Plate Set

6 PRECISION ROTARY TABLE (HV6) – 3 SLOTS WITH INDEXING PLATE KIT. 6 Center Bore – MT2 No. Of Slots – 3 Model – HV6 (Horizontal / Vertical) Gear Ration – 90 : 1 T-Slot 16mm 5/8 approx. 80 mm from Base to Top surface of Chuck Graduated 360 degree around its circumference and driven by precision gear with 1:90 reduction ratio. One turn by handle moves table 4 degrees. Manufactured from high grade seasons casting and powder coated wrinkled finish for smooth finish. Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. Comes complete with necessary screws, washers & handles. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.