milling

150mm 6in 4-Slot Horizontal Vertical Rotary Milling Table

[VERTICAL & HORIZONTAL]- Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. [REMARKABLE QUALITY]- Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. [EXCELLENT PRECISION]- The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. [CONVENIENT TO ADJUST]- The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. [MULTIPLE APPLICATION]- With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 6/150mm Rotary Table 4-Slot Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate. VEVOR is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, has occupied markets of more than 200 countries with 10 million plus global members. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. Clear scale is more convenient for you to operate it. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Three dividing plate set(Plate’A’ – 15, 16, 17, 18, 19, 20 Plate’B’ – 21, 23, 27, 29, 31, 33 Plate’C’ – 37, 39, 41, 43, 47, 49). A set of wrench and screws are free for you with your installation. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Model: 6 inch Rotary Table. T-slot Diameter: 1/2 inch / 14 mm. Table Dimension: 6 inch / 150 mm. Plate’A’ – 15, 16, 17, 18, 19, 20. Plate’B’ – 21, 23, 27, 29, 31, 33. Plate’C’ – 37, 39, 41, 43, 47, 49. Setting Position: Horizontal / Vertical. Item Weight: 40 lbs / 18.18 kg. Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm. 1 x Rotary Table. 3 x Dividing Plates. 1 x A Set of Accessories.

8 Inch/200 MM Rotary Table Horizontal Vertical for Milling 360°Precision Working

8/200mm Rotary Table 3-Slot / 4-Slot Horizontal Vertical Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. 8 Vertical & Horizontal Design. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. Just adjust the handle to the position where you want as the precise scale is marked on the dial. Free Wrench & Screw. A wrench and screws are free for you with your installation the vertical & horizontal rotary table. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Table Diameter: 8/200mm. Reduction ratio: 1:90. Horizontal Height : 4.13/105mm. Vertical Height : 1.57/40mm. 1 x Vertical and Horizontal Rotary Working Table. 1 x Screw Set. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table. 8″ Vertical & Horizontal Design: Our rotary table for milling machine is 8″ / 200 mm with 3 slots or 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. Excellent Precision: The precision rotary table’ indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: With free wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs.

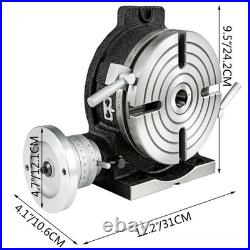

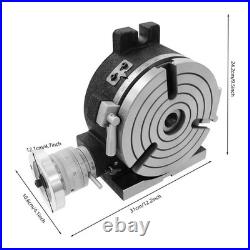

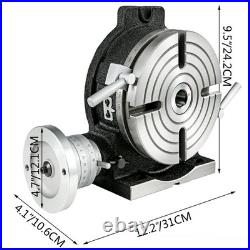

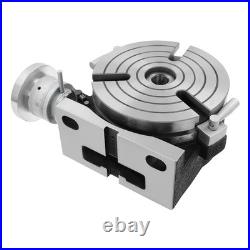

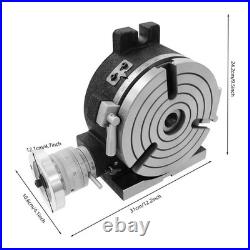

3-slot Rotary Table Horizontal Vertical Rotable Tool Holding for Milling Machine

Specifications Material: FC30 Cast Iron Color: Black, Silver Mounting Required: Yes Number of T-Slot: 3 Worm Gear Transmission Ratio: 1:90 Worm Gear Module: 1.5mm/0.06inch Max. Load Capacity (Horizontal): 100kg/220 lbs Max. Load Capacity (Vertical): 50kg/110 lbs Indexing Accuracy: 0.05° Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1° Large Wheel Scale Range: 360° Gross Weight: 12.6kg/27.78 lbs Net Weight: 12.06kg/26.59 lbs Handwheel Diameter: 12.1cm/4.7inch Product Size (Vertical): 3110.624.2cm/12.24.19.5inch Package Size: 31.52616cm/12.410.246.3inch Package Included 1 3-slot Rotary Table Other Accessories for Installation. 3-slot Rotary Table Horizontal Vertical Rotable Tool Holding for Milling Machine. It is compatible with milling machines to perform various tasks, such as indexed drilling, milling, circular cutting, boring, and more. Material: FC30 Cast Iron. Number of T-Slot: 3. Worm Gear Transmission Ratio: 1:90. Worm Gear Module: 1.5mm/0.06inch. Load Capacity (Horizontal): 100kg/220 lbs. Load Capacity (Vertical): 50kg/110 lbs. Indexing Accuracy: 0.05°. Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1°. Large Wheel Scale Range: 360°. Gross Weight: 12.6kg/27.78 lbs. Net Weight: 12.06kg/26.59 lbs. Handwheel Diameter: 12.1cm/4.7inch. : 3110.624.2cm/12.24.19.5inch. Package Size: 31.52616cm/12.410.246.3inch. Other Accessories for Installation. Crafted from FC30 cast iron, it exhibits superior wear endurance and structural solidity, establishing a reliable foundation for the product’s extended service life. Featuring a worm gear ratio of 1:90 and a module of 0.06 inches, it delivers smooth, powerful transmission. With an indexing accuracy of 0.05°, it meets the stringent precision demands of machining positioning. What’s more, the easy-to-read clear graduations bring great convenience for use. It supports a maximum load of 220 lbs in horizontal mode and 110 lbs in vertical mode. This flexible load capacity adapts to diverse processing needs, accommodating workpieces of varying weights with ease. It features a precision handwheel where 30 small scales equal 1°, and one full handwheel rotation corresponds to 4°. The larger wheel provides a 360° scale range, supporting detailed and accurate angular positioning during machining. Fitted with an innovative spindle locking mechanism, it delivers a stronger clamping force than conventional double-sided pressure plate designs. This ensures exceptional stability during use processes, directly boosting machining precision and safety. Please carefully check if the size is suitable before placing an order. Please use the product within its weight capacity to avoid damage. Please allow for slight color differences caused by the shooting light and a 1-3cm error due to manual measurement, and make sure you do not mind before ordering. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday. High performance?? reliable quality?? good stability. Nice and Practical, High Quality Packaging, Easy installation. Worm Gear Transmission Ratio. Graduated Ring of the Handwheel Scale. 4° (A Whole Circle)/30 Small Scales Equal 1°. Large Wheel Scale Range. 3110.624.2cm/12.24.19.5inch.

Rotary Table Horizontal Vertical Rotary Table for Milling 360 Degrees Working

SucceBuy 8/200mm Rotary Table. Versatile and Precision Engineered for Your Milling Needs! The SucceBuy Rotary Table is an essential accessory for milling machines, designed to enhance precision in work positioning. This versatile tool excels in applications such as indexing, drilling, milling, circumferential cutting, and boring. Crafted from high-quality HT200 cast iron, it meets ISO9001 quality standards, ensuring reliable performance. With its superior design and competitive pricing, this rotary table is a popular choice among professionals. 8 Design for Both Vertical and Horizontal Use. Exceptional Build Quality for Durability. High Precision for Accurate Operations. Suitable for Various Applications. Easy to Adjust for User Convenience. Constructed from high-quality HT200 cast iron, the milling table exhibits excellent casting characteristics, providing effective shock absorption and impressive heat resistance for enhanced durability. This rotary table offers both vertical and horizontal configurations, enabling a variety of tasks such as circle cutting, indexing drilling, and milling, especially when paired with the tail part for more complex operations. Ideal for a wide range of tasks, this rotary table is perfect for milling, drilling, fixture boring, and various common workshop applications. The dial features a full 360-degree scale, with the handle adjusting by 4 degrees per rotation, allowing for precise readings down to 10 seconds for meticulous work. Easily position the table by adjusting the handle to your desired location, with clear, precise markings on the dial for convenience. Included Wrench and Screws. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table. High-Quality Construction: Crafted from HT200 casting, this rotary table is designed to withstand pressure and vibration, providing exceptional durability. Its shock-absorbing and heat-resistant properties ensure reliable performance in various conditions. Outstanding Accuracy: The indexing plate of the precision rotary table is graduated to 360 degrees, allowing for precise adjustments. The resetting dial and hand wheel can be calibrated in seconds, with a minimum scale of 10 seconds for enhanced precision. Wide Range of Applications: Accompanied by a free wrench and a set of screws, this rotary table is compatible with various milling machines. It is suitable for tasks like index boring, milling, circle cutting, spot facing, and drilling holes, catering to diverse workshop needs. User-Friendly Adjustments: Featuring a clearly marked scale on the dial, adjustments are straightforward. Simply operate the control handle to reach your desired position, ensuring ease of use and convenience during operation. Versatile Functionality: This rotary table features an 8 / 200 mm design with three slots, allowing for both horizontal and vertical use. This dual functionality enhances your milling experience, making it more convenient and efficient.

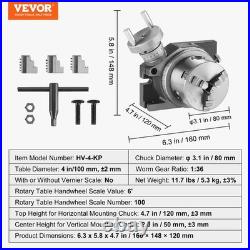

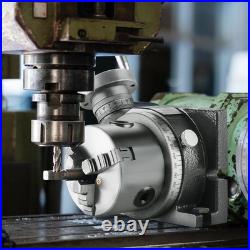

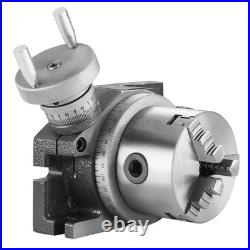

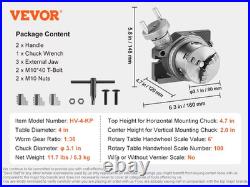

For Rotary Table For Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

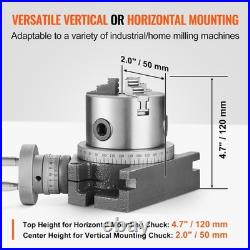

VEVOR VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. Horizontal & Vertical Installation: When mounted horizontally, the chuck top heigh.. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. VEVOR VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm?? 3 mm, and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! New Air Compressor Filter Regulator, 3/8 NPT Dual Stage Air-Drying System with. New Suction Pool Cleaner, Automatic Pool Vacuum Cleaner, Suction Side Automatic. Track Torch Burner 2″-30″/Min 0.2″-4″ Straight Line Gas Cutting Machine. New Demolition Jack Hammer, 3000 W Powerful Electric Jackhammer, 1700 BPM Concr. New Frameless Ski Goggles, Magnet Cylindrical Lens with Dark Blue Revo Coating. New 5-Tier Water Jug Holder Double Row Water Bottle Rack New 10 Bottles Black. New Sheet Sander, 1/2 Sheet 2.5A Electric Sander New Woodworking, Max. New Kids Play Tent, Kids Tent New Kids 1-5 Years Old, Toddler Tent with Mat an.

Precision Milling Rotary Table 4”/100Mm Horizontal Vertical Model with 3-Jaw Ch

4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn. 4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our? 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter:? 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”- 0.98” / 2-25 mm, Internal Clamping Range: 0.98”- 2.76”/ 25-70 mm. It includes an external jaw and external clamping range of 0.87”-2.76” / 22-70 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (±3 mm), and when mounted vertically, the chuck center height is 3.4” / 86 mm (±3 mm). Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations.

Pro Rotary Table 6 4-Slot Horizontal Vertical Dividing Plates Milling Machine

6/150mm Rotary Table 4-Slot Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. Clear scale is more convenient for you to operate it. Just adjust the handle to the position where you want as the precise scale is marked on the dial. 150 mm Rotary Table. It has a size of 150 mm, making it compact and efficient. It fits easily on most milling machines. The table is ideal for small to medium projects. Despite its compact size, it allows for high precision and accuracy. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Model: 6 inch Rotary Table. T-slot Diameter: 1/2 inch / 16 mm. Table Dimension: 6 inch / 150 mm. Setting Position: Horizontal / Vertical. Item Weight: 15 kg. 1 x Rotary Table. 1 x A Set of Accessories. VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs.

Horizontal Vertical Rotary Table 3-Slot Rotary Table Rotary Table for Milling

Specifications Material: FC30 Cast Iron Color: Black, Silver Mounting Required: Yes Number of T-Slot: 3 Worm Gear Transmission Ratio: 1:90 Worm Gear Module: 1.5mm/0.06inch Max. Load Capacity (Horizontal): 100kg/220 lbs Max. Load Capacity (Vertical): 50kg/110 lbs Indexing Accuracy: 0.05° Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1° Large Wheel Scale Range: 360° Gross Weight: 12.6kg/27.78 lbs Net Weight: 12.06kg/26.59 lbs Handwheel Diameter: 12.1cm/4.7inch Product Size (Vertical): 3110.624.2cm/12.24.19.5inch Package Size: 31.52616cm/12.410.246.3inch. Horizontal Vertical Rotary Table 3-Slot Rotary Table Rotary Table for Milling. Crafted for high-precision mechanical processing, the 3-slot rotary table is a sophisticated precision device. Built from FC30 cast iron and incorporating cutting-edge technologies, it maintains sturdiness even under rigorous machining conditions. Its ability to switch between horizontal and vertical modes allows it to adapt to a wide range of machining tasks, solidifying its role as a powerful tool for enhancing both machining accuracy and efficiency. Crafted from FC30 cast iron, it exhibits superior wear endurance and structural solidity, establishing a reliable foundation for the product’s extended service life. Featuring a worm gear ratio of 1:90 and a module of 0.06 inches, it delivers smooth, powerful transmission. With an indexing accuracy of 0.05°, it meets the stringent precision demands of machining positioning. What’s more, the easy-to-read clear graduations bring great convenience for use. It supports a maximum load of 220 lbs in horizontal mode and 110 lbs in vertical mode. This flexible load capacity adapts to diverse processing needs, accommodating workpieces of varying weights with ease. It features a precision handwheel where 30 small scales equal 1°, and one full handwheel rotation corresponds to 4°. The larger wheel provides a 360° scale range, supporting detailed and accurate angular positioning during machining. Fitted with an innovative spindle locking mechanism, it delivers a stronger clamping force than conventional double-sided pressure plate designs. This ensures exceptional stability during use processes, directly boosting machining precision and safety. They enable firm, adaptable installation on a range of machining equipment, ensuring stable positioning during use. A reset screw located beneath the handwheel’s graduated ring simplifies calibration. Loosening this screw allows quick, zero-resetting of the scales, facilitating precise adjustments for tasks. It is compatible with milling machines to perform various tasks, such as indexed drilling, milling, circular cutting, boring, and more. Material: FC30 Cast Iron. Number of T-Slot: 3. Worm Gear Transmission Ratio: 1:90. Worm Gear Module: 1.5mm/0.06inch. Load Capacity (Horizontal): 100kg/220 lbs. Load Capacity (Vertical): 50kg/110 lbs. Indexing Accuracy: 0.05°. Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1°. Large Wheel Scale Range: 360°. Gross Weight: 12.6kg/27.78 lbs. Net Weight: 12.06kg/26.59 lbs. Handwheel Diameter: 12.1cm/4.7inch. : 3110.624.2cm/12.24.19.5inch. Package Size: 31.52616cm/12.410.246.3inch. Other Accessories for Installation. Please carefully check if the size is suitable before placing an order. Please use the product within its weight capacity to avoid damage. Please allow for slight color differences caused by the shooting light and a 1-3cm error due to manual measurement, and make sure you do not mind before ordering. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.

Rotary Tables 6 4-Slot Horizontal Vertical Dividing Plates Milling Machine Tool

6/150mm Rotary Table 4-Slot Rotary Table. The mill rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring, etc. The rotary turn table for milling machine is made from casting with high quality, can work with a set of dividing plate. Vertical & Horizontal Design. Both vertical and horizontal with two functions. Circle cutting, indexing drilling, milling and more complicated work are possible when the vertical position of the table is used together with the tail part. Milling table is of good casting performance like mill vise, shock absorption performance as well as high strength heat resistance. The dial is divided into 360 degrees in total. Clear scale is more convenient for you to operate it. Just adjust the handle to the position where you want as the precise scale is marked on the dial. 150 mm Rotary Table. It has a size of 150 mm, making it compact and efficient. It fits easily on most milling machines. The table is ideal for small to medium projects. Despite its compact size, it allows for high precision and accuracy. Rotary table milling machines are designed for milling, drilling, fixture boring and many common workshop applications. Model: 6 inch Rotary Table. T-slot Diameter: 1/2 inch / 16 mm. Table Dimension: 6 inch / 150 mm. Setting Position: Horizontal / Vertical. Item Weight: 15 kg. 1 x Rotary Table. 1 x A Set of Accessories. VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs.