milling

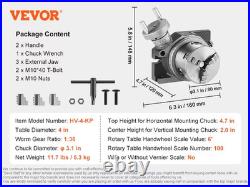

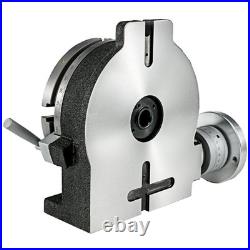

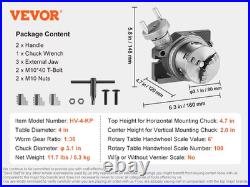

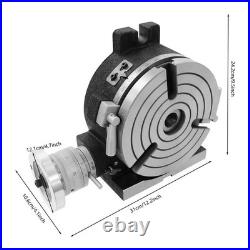

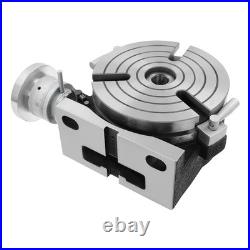

Precision Milling Rotary Table 4”/100Mm Horizontal Vertical Model with 3-Jaw Ch

4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn. 4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our? 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter:? 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”- 0.98” / 2-25 mm, Internal Clamping Range: 0.98”- 2.76”/ 25-70 mm. It includes an external jaw and external clamping range of 0.87”-2.76” / 22-70 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (±3 mm), and when mounted vertically, the chuck center height is 3.4” / 86 mm (±3 mm). Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations.

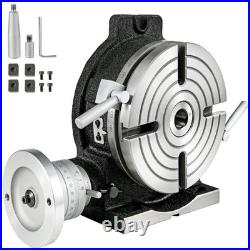

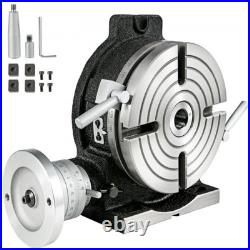

VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm)

VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling DrillingVertical & Horizontal DesignDurable Casting MaterialHighly PrecisionEasy To AdjustConsiderate Assembly KitsVarious ApplicationCentre Bore: MT-2, Plate’B’ – 21, 23, 27, 29, 31, 33:, Model: 6 inch Rotary Table, Plate’C’ – 37, 39, 41, 43, 47, 49:, Material: Cast Iron, Setting Position: Horizontal / Vertical, Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm, Table Dimension: 6 inch / 150 mm, Plate’A’ – 15, 16, 17, 18, 19, 20:, T-slot Diameter: 1/2 inch / 14 mm, Item Weight: 40 lbs / 18.18 kg? MULTIPLE APPLICATION? – With a set of wrench and set of screws, the powe.. VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling Drilling. VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling Drilling Vertical & Horizontal Design Durable Casting Material Highly Precision Easy To Adjust Considerate Assembly Kits Various Application Centre Bore: MT-2, Plate’B’ – 21, 23, 27, 29, 31, 33:, Model: 6 inch Rotary Table, Plate’C’ – 37, 39, 41, 43, 47, 49:, Material: Cast Iron, Setting Position: Horizontal / Vertical, Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm, Table Dimension: 6 inch / 150 mm, Plate’A’ – 15, 16, 17, 18, 19, 20:, T-slot Diameter: 1/2 inch / 14 mm, Item Weight: 40 lbs / 18.18 kg. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. If an unit is received defective, of course we take it back or replace it. If the unit is received as expected, we must charge for our expenses if you want to send it back. Thank you for visiting my store! Our warehouses are located in many regions around the United States. Prioritize the best quality logistics solutions to transport packages. At the same time. Have any after-sales problems. VEVOR Ultrasonic Cleaner for Dentures 200ML Retainer Cleaner Machine UV Light 30. VEVOR Cigarette Rolling Machine Solid Brass Cigarette Roller Manual Tobacco Roll. VEVOR Tripod Guitar Stand 33 lbs/15 kg Load Capacity Floor-Standing Foldable Gui. VEVOR Grommet Tool Kit 500 PCS 3/8 Inch Metal Eyelets Grommets in Gold Silver Ey. VEVOR Coil Spring Compressor Tool 2 pcs Heavy Duty Macpherson Strut Spring Compr. VEVOR Metal Raised Garden Bed 4 x 2 x 1 ft Outdoor Galvanized Planter Box Open B. VEVOR Engine Toy 60 Pieces Kids Mechanic Car Repair Set Removable Parts Lights S. VEVOR Light Sword 38 Light up Sword 12 RGB Colors FX Sound Realistic Handle Rec. VEVOR Magnetic Tiles 55 PCS Magnetic Building Blocks for Kids Magnet Building Se. VEVOR Mechanical Keyless Entry Door Lock 14 Key Mechanical Door Lock Mechanical.

VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm)

VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling DrillingVertical & Horizontal DesignDurable Casting MaterialHighly PrecisionEasy To AdjustConsiderate Assembly KitsVarious ApplicationCentre Bore: MT-2, Plate’B’ – 21, 23, 27, 29, 31, 33:, Model: 6 inch Rotary Table, Plate’C’ – 37, 39, 41, 43, 47, 49:, Material: Cast Iron, Setting Position: Horizontal / Vertical, Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm, Table Dimension: 6 inch / 150 mm, Plate’A’ – 15, 16, 17, 18, 19, 20:, T-slot Diameter: 1/2 inch / 14 mm, Item Weight: 40 lbs / 18.18 kg? MULTIPLE APPLICATION? – With a set of wrench and set of screws, the powe.. VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling Drilling. VEVOR Rotary Table 6inch(150mm) Horizontal Vertical Milling Table 2/5inch(10mm) 4-Slot Milling Rotary Table MT-2 Rotary Table for Milling with Indexing Plate Set for Precision Milling Drilling Vertical & Horizontal Design Durable Casting Material Highly Precision Easy To Adjust Considerate Assembly Kits Various Application Centre Bore: MT-2, Plate’B’ – 21, 23, 27, 29, 31, 33:, Model: 6 inch Rotary Table, Plate’C’ – 37, 39, 41, 43, 47, 49:, Material: Cast Iron, Setting Position: Horizontal / Vertical, Item Dimensions: 9.5 x 3.1 x 7.7 inch / 24.2 x 8.1 x 19.8 cm, Table Dimension: 6 inch / 150 mm, Plate’A’ – 15, 16, 17, 18, 19, 20:, T-slot Diameter: 1/2 inch / 14 mm, Item Weight: 40 lbs / 18.18 kg. MULTIPLE APPLICATION? – With a set of wrench and set of screws, the power milling machines are widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. CONVENIENT TO ADJUST? – The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. EXCELLENT PRECISION? – The precision rotary table indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. REMARKABLE QUALITY? – Cast iron mainly used to cast parts subjected to pressure and vibration on mechanical equipment, offering rotary table for milling durability, shock absorption and heat-resistantance. VERTICAL & HORIZONTAL? – Our rotary table for milling machine is 6/150mm with 4 slot can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. If an unit is received defective, of course we take it back or replace it. If the unit is received as expected, we must charge for our expenses if you want to send it back. Thank you for visiting my store! Our warehouses are located in many regions around the United States. Prioritize the best quality logistics solutions to transport packages. At the same time. Have any after-sales problems. VEVOR Electric Trailer Brake Assembly 12″ x 2″ 1 Pair Self-Adjusting Electric Br. Male Enhancing 60 Gummies?? Massive Girth Enlargement Extreme. VEVOR 50 Pcs Joist Hanger Inner Dimensions 1.57 x 1.50 x 7.83 inch / 40 x 38 x 1. Himalayan GOLD Gummies-BOOSTER-Performance Surge 60 Tablets Xmas Men Gift. VEVOR Hearing Aids for Seniors Rechargeable Hearing Amplifiers Noise Cancelling. Digestive Enzymes Prebiotic&Probiotics Gas, Constipation&Bloating Relief. Turmeric Curcumin 1950 mg High Absorption Extra Strength Vegan Capsules 60 Ct. Red Korean Panax Ginseng 1600mg 120 Capsules-Energy/Endurance/Memory/Sex Drive. Organic Turmeric Curcumin 10000mg-95% High Strength Capsules with Black Pepper. Berberine Supplement 1200mg per Serving-High Absorption Heart Health Support.

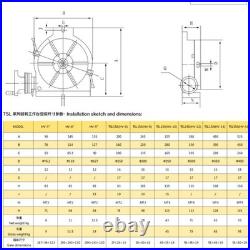

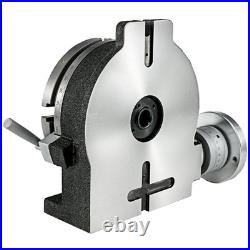

HV5 125mm Rotary Table Vertical/Horizontal Indexing for Milling Machine

HV5 125mm High Precision Rotary Table, Vertical/Horizontal Indexing for Milling Machine. The HV5 is a professional-grade, high-precision vertical and horizontal rotary table, an essential accessory for any milling machine. It enables precise indexing, circular milling, drilling, and boring operations with exceptional accuracy (minimum division of 10). Crafted from high-strength cast iron and featuring a robust 1:90 worm gear drive, it’s built for stability and longevity in demanding workshop environments. Key Features & Applications. Can be used securely in both horizontal and vertical positions, greatly expanding its range of applications on the mill. Features a 360° graduated scale, a vernier ring with a minimum reading of 10 seconds of arc, and a precise 1:90 reduction ratio for accurate angular positioning. The improved spindle locking system provides stronger clamping force and more vibration-resistant stability during cuts compared to traditional designs. Wide Range of Uses. Perfect for indexing, circular cutting, drilling, boring, and milling complex workpieces. In the vertical position, it can be used with an optional tailstock. Made of high-strength FC30 cast iron for durability and reduced vibration. Vertical/Horizontal Rotary Indexing Table. High-Strength FC30 Cast Iron. 1° per handle turn (4° per full turn). Braking Mechanism, Worm Disengagement for rapid positioning, Optional Honeycomb Plate & Tailstock available. Milling Machine Accessory for indexing, drilling, milling, boring. 1 x HV5 Precision Rotary Table.

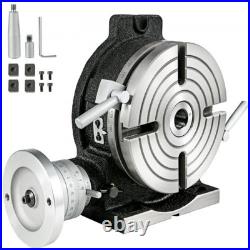

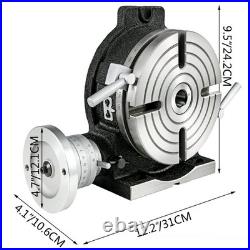

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling BoringVertical & Horizontal DesignHT200 CastingExcellent PrecisionEasy to AdjustWrench & ScrewVarious ApplicationVertical Height : 40 mm/1.57″, Horizontal Height : 105 mm/4.13″, Material: HT200 Casting, Table Diameter: 8″, Reduction ratio: 1:90, Center Bore: MT-3 Multiple Application: Designed to be widely used” milling machine likedex boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily.. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57″, Horizontal Height : 105 mm/4.13″, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3. Multiple Application: Designed to be widely used” milling machine like”dex boring, milling, circle cutting, spot facing and boring hole and so on. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: Thedexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated seconds. The minimum scale is calibrated to 10 seconds with high precision. Vertical & Horizontal Design: Our precise rotary table is 8″ with 4 slots can be used” both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Milling & Drilling Accessories. If an unit is received defective, of course we take it back or replace it. If the unit is received as expected, we must charge for our expenses if you want to send it back. Thank you for visiting my store! Our warehouses are located in many regions around the United States. Prioritize the best quality logistics solutions to transport packages. At the same time. Have any after-sales problems. 2PCS Left&Right Turbocharger for Ford Flex, Explorer/Lincoln MKS, MKT 3.5L. VEVOR Garage Storage Shelving, 2 Pack, 4×1 ft Heavy Duty Garage Shelves Wall Mount. VEVOR Pool Drain Hose, 2 by 50 ft, Durable PVC Material, Includes Aluminum Cam. VEVOR L Screen Baseball for Batting Cage, 7×7 ft Softball Safety Screen, Body Prot. VEVOR Pottery Wheel, 350W Electric Wheel for Pottery with Foot Pedal and LCD Touc.

3MT 8in Precision Rotary Table Horizontal Vertical Milling Drilling Vernier

Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. 8 Vertical & Horizontal Rotary Table. The vertical & horizontal rotary table is one of the main accessories of milling machine. As a precision work positioning device, it is widely used for indexing drilling, milling, circumferential cutting, boring and so on. Our amazing rotary table is made from HT200 casting with high quality. It has already passed the ISO9001 quality system certification. They are are very popular on the market for their superior performance, excellent design and reasonable cost. They are definitely your best choice! Vertical & Horizontal Design. Unbranded is a leading brand that specializes in equipment and tools. Along with thousands of motivated employees, Unbranded is dedicated to providing our customers with tough equipment & tools at incredibly low prices. Today, Unbranded has occupied markets of more than 200 countries with 10 million plus global members. Our rotary table is both vertical and horizontal with two functions. When the vertical position of the table is used together with the tail part, it is also possible to complete circle cutting, indexing drilling, milling and more complicated work. HT200 casting has good casting performance, shock absorption performance as well as high strength heat resistance. It ensures the of superior performance the machine and provides you a good sense of use. The dial is divided into 360 degrees in total. The handle is 4 degrees per revolution. The minimum scale can be accurate to 10 seconds. All of these help you handle more complex and more precise tasks. It’s not difficult for you to adjust the rotary table milling machine. What you should to do is just adjust the handle to the position where you want. Because the precise scale is marked on the dial. When you install the vertical & horizontal rotary table, these accessories will bring you a lot of conveniences. This machine is designed for milling, drilling, fixture boring and many common workshop applications. It makes it possible for operators to drill or cut work at exact intervals around a fixed axis in the process of working. Reduction ratio: 1:90. Horizontal Height : 105 mm/4.13 inch. Vertical Height : 40 mm/1.57 inch. 2 x Positioning Keys. 2 x Mounting Screws. 1 X Vertical and Horizontal Rotary Working Table.

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling BoringVertical & Horizontal DesignHT200 CastingExcellent PrecisionEasy to AdjustWrench & ScrewVarious ApplicationVertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3 Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to us.. Best choice of motor parts. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Vertical & Horizontal Design: Our precise rotary table is 8with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. If an unit is received defective, of course we take it back or replace it. If the unit is received as expected, we must charge for our expenses if you want to send it back. Thank you for visiting my store! Our warehouses are located in many regions around the United States. Prioritize the best quality logistics solutions to transport packages. At the same time. Have any after-sales problems.

Precision Milling Rotary Table 4”/100Mm Horizontal Vertical Model with 3-Jaw Ch

4-Inch Rotary Table for Milling Machine. Our 4”/100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4-inch rotary table and take your milling projects to the next level of accuracy. Our rotary table comes with a 3-jaw chuck and requires additional installation! We offer two types of jaws, internal jaw and external jaw, which easily open and close with a T-shaped chuck wrench, ensuring a secure and precise grip on your workpieces. Enjoy the precise machining with our meticulously designed milling rotary table featuring a worm gear ratio of 1:36 and a fine, clear scale. Every rotation is under your control, with a dedicated degree lock. Once you set your angle, it stays put, ensuring stability and consistency in your work. Discover unparalleled versatility with our milling machine rotary table, ingeniously designed for both horizontal and vertical applications. The precise positioning slot on the bottom ensures the rotary table remains stable and shake-free during operation. Our rotary table is crafted from HT250 cast iron for exceptional wear resistance and high hardness and is a staple in precision and heavy-duty machining industries. Choose our rotary table for a lasting addition to your workshop, where strength meets precision at every turn. 4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our? 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter:? 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”- 0.98” / 2-25 mm, Internal Clamping Range: 0.98”- 2.76”/ 25-70 mm. It includes an external jaw and external clamping range of 0.87”-2.76” / 22-70 mm. Enjoy the precise and secure machining of small components! High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (±3 mm), and when mounted vertically, the chuck center height is 3.4” / 86 mm (±3 mm). Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations.

3-Slot Rotary Table Horizontal Vertical Rotable Tool Holding for Milling Machine

Cs-head{overflow:hidden;position:relative}. Title{margin:0;font-weight:400;font-size:14px;padding:5px 10px}. Dc-dock:hover{width:117px;background-position:bottom right}. Dc-cs{clear:both;max-width:100vw}. Dock-rb{right:0;bottom:0}. Title{font-weight: 700;font-size: 18px}. Title:after{content:’You may like';color: #FFFFFF}. Cs-list>li:nth-child(n+21){display:none}. Title{margin:0;font-weight: 700;font-size: 18px}. Cs-list>li:nth-child(n+7){display:none}. Coupon{transform-origin:right top;right:0}. Cs-list{margin:0 0 0 -20px;padding:0;background:#FFF}. Cs-list:before{display:table;line-height:0;content:}. Cs-list:after{clear:both}. Cs-list>li{float:left;width:16.66%;list-style:none;box-sizing:border-box;padding:10px 0 10px 20px;position:relative;margin:0}. Cs-list-col6>li{width:16.66%}. Cs-list-col7>li{width:14.28%;padding-left:18px}. Cs-list-col8>li{width:12.5%;padding-left:16px}. Cs-list-col9>li{width:11.11%;padding-left:15px}. Cs-list-col10>li{width:10%;padding-left:14px}. Cs-list-col11>li{width:9.09%;padding-left:12px}. Cs-list-col12>li{width:8.33%;padding-left:10px}. Cs-list>liwidth:33.33%! Cover:after{display:block;content:”;padding-top:100%;background-repeat:no-repeat;background-size:cover;background-position:center}. Cs-list a{text-decoration:none}. Title{color:#333;margin:5px 0}. Title:after{display:block;display:-webkit-box;-webkit-line-clamp:2;-webkit-box-orient:vertical;font-size:14px;line-height:1.4em;height:2.8em;overflow:hidden;white-space:normal;word-break:break-word;-webkit-hyphens:auto;-ms-hyphens:auto;hyphens:auto}. Plus{height:20px;overflow:hidden}. Price:after{content:”;font-size:14px}. Origin{margin-left:3px;font-size:12px;color:#AAA}. Origin:after{display:none;content:”;text-decoration:line-through}. Coupon{display:none;width:60px;height:60px;border-radius:50%;background:rgba(224,13,12.8);color:#FFF;position:absolute;top:10px;right:10px;text-align:center;padding-top:12px;box-sizing:border-box}. Coupon:before{content:”;font-size:20px}. Coupon:after{content:’Off';font-size:12px;position:absolute;bottom:8px;right:12px}. Title{min-height:12px}p:empty+hr{display:none}hr+span. Dc_tracker_img{display:none}#ds_div>. Dc_tracker_img:last-of-type{display:block} [data-lid=”167927509032″]. Title:after{content:’110V Digital Length Meter Counter Electronic Distance Meter Counter Tool’}[data-lid=”167927509032″]. Title:after{content:’60W Wall Mounted Light Bedroom Reading Lamp Plug in Wall Sconces Set w/ Switch’}[data-lid=”167927481452″]. Title:after{content:’Electric Winch, 3000 Lbs Electric Winch Kit, Electric Winch With Wired Control’}[data-lid=”167927474451″]. Title:aftercontent:’Ultra Clamp Pipe Clamp 2\\.