milling

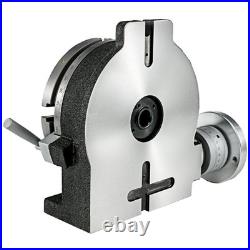

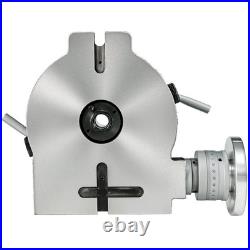

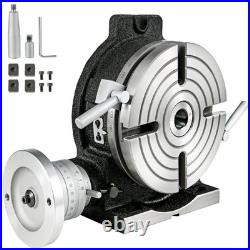

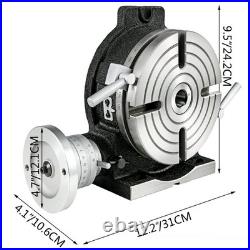

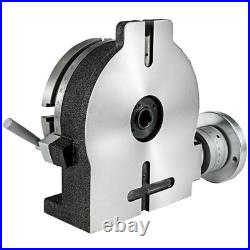

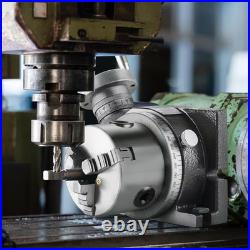

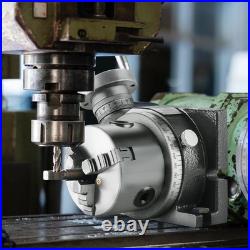

New Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

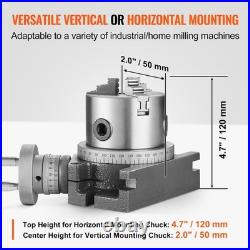

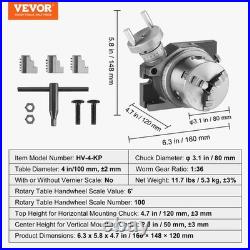

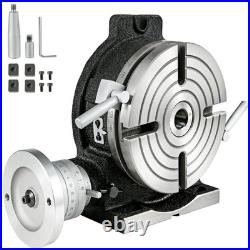

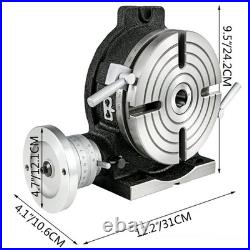

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4… VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm (±3 mm), and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. Chuck Diameter:? 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! 4-Inch Milling Machine Rotary Table: Elevate your milling capabilities with our? 4” / 100 mm rotary table, which is ideal for small milling machines. It is designed for precise positioning, rotation, indexing, and clamping of wood and metal workpieces for curved surface machining, elongated hole processing, and precision drilling. Widely used in automotive, mold-making, and general machinery, underscores its essential role in mechanical processing.

Precision 3 (75mm) Mini Rotary Table Horizontal & Vertical Milling Tool

Precision Engineered (ART Series): Designed For Accuracy With Ground Surfaces And Tight Machining Tolerances. Regular Rotary Table Design: Reliable Performance For Daily Workshop And Industrial Milling Needs. Multiple Sizes & Variants: Available In 3″ (75 mm) & 4″ (100 mm) Sizes With 3-slot And 4-slot Options. HV Model Option: Switch Easily Between Horizontal And Vertical Machining Setups With HV Models. Durable Construction: Manufactured From Premium Cast Iron For Long Life And Stability. Wide Applications: Perfect For Drilling, Cutting Arcs, Indexing, Angle Setting, And Other Milling Tasks.

Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machin

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MTMilling Drilling Machine Vernier Reading Milling DrillingBoring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio:1:90, Center Bore: MT-3.

New Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Vertical & Horizontal Design.. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant.

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling

VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling BoringVertical & Horizontal DesignHT200 CastingExcellent PrecisionEasy to AdjustWrench & ScrewVarious ApplicationVertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3 Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Practical design can meet a variety of workshop work needs. Convenient to Adjust: The dial is marked with an accurate scale. Just operate the control handle and adjust it to the desired position, which makes it possible to us.. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring. VEVOR Rotary Table 8Inch Horizontal Vertical HV8 Precision 3MT Milling Drilling Machine Vernier Reading Milling Drilling Boring Vertical & Horizontal Design HT200 Casting Excellent Precision Easy to Adjust Wrench & Screw Various Application Vertical Height : 40 mm/1.57 inch, Horizontal Height : 105 mm/4.13 inch, Material: HT200 Casting, Table Diameter: 8, Reduction ratio: 1:90, Center Bore: MT-3. Multiple Application: Designed to be widely used in milling machine like index boring, milling, circle cutting, spot facing and boring hole and so on. Just operate the control handle and adjust it to the desired position, which makes it possible to use it easily and conveniently. Excellent Precision: The indexing plate can be graduated 360 Degrees. Resetting dial and hand wheel can be graduated in seconds. The minimum scale is calibrated to 10 seconds with high precision. Vertical & Horizontal Design: Our precise rotary table is 8 with 4 slots can be used in both horizontal and vertical positions, meeting two functions and also bringing you convenient as well as efficient milling experience. Remarkable Quality: HT200 Casting is mainly used to cast parts subjected to pressure and vibration on mechanical equipment. Using it as the material, our products are durable, shock-absorbing and heat-resistant. Play Couch, Modular Kids Nugget Couch 15pcs, Toddler Foam Sofa Couch with High-d. VEVOR 6-8 Person Ourdoor Portable Ice Shelter Pop-Up Ice Fishing Shanty Tent. Laptop Cart, 32 Device Mobile Open Charging Station, Up to 15.6 in Screen Size. 20 in Glass Lazy Susan Turntable, 360° Rotation Round Clear Tabletop Rotating Tr. VEVOR Stainless Steel Quarter Fenders for Semi Trucks, 24″ x 24″ Semi Truck Fend. VEVOR Tenon Cutter, 1.5 / 38 mm Diameter, Premium Aluminum & Steel Log Furnitur. VEVOR Manual Lever Chain Hoist, 1/2 Ton 1100 lbs Capacity 5 FT Come Along, G80 G. VEVOR Tire Bead Setter, 8L Capacity, 120 PSI Air Bead Blaster, Handheld & Portab. VEVOR Drive Clutch, 2-8HP Engine, 2000 RPM High-Strength Drive Clutch with Asymm. VEVOR Water Diaphragm Pump, 110V AC, 3.3 GPM Flow, 45 PSI Rated Pressure 40-80.

Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Preci

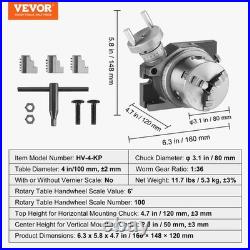

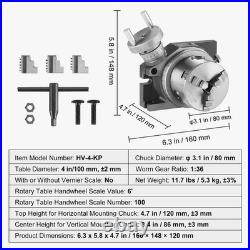

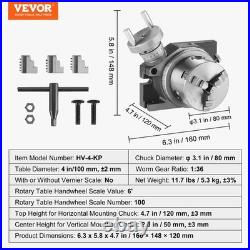

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, HorizontalVertical Model Precision Milling Rotary Table, with 3.1”/80 mm3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering IndexingTools 4-Inch Rotary Table for Milling Machine 3-Jaw Chuck Clear Scale Horizontal & Vertical Use Superior Hardness Dual Handle Design Rotary Table Handwheel Scale Number: 100, Top Height for HorizontalMounting Chuck: 4.7 in / 120 mm, ±3 mm, Rotary Table Handwheel ScaleValue: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical MountingChuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or WithoutVernier Scale: No, Chuck Diameter:? 3.1 in / 80 mm, Table Diameter:4 in / 100 mm, ±2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160 ×148 × 120 mm, Net Weight: 11.7 lbs / 5.3 kg ± 3%.

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools4-Inch Rotary Table for Milling Machine3-Jaw ChuckClear ScaleHorizontal & Vertical UseSuperior HardnessDual Handle DesignRotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ?? 3 mm, Rotary Table Handwheel Scale Value: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical Mounting Chuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or Without Vernier Scale: No, Chuck Diameter:?? 3.1 in / 80 mm, Table Diameter: 4 in / 100 mm, ?? 2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160?? 120 mm, Net Weight: 11.7 lbs / 5.3 kg? .. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools 4-Inch Rotary Table for Milling Machine 3-Jaw Chuck Clear Scale Horizontal & Vertical Use Superior Hardness Dual Handle Design Rotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ?? 120 mm, Net Weight: 11.7 lbs / 5.3 kg?? Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm?? 3 mm, and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! Please allow slightly longer for weekends and national holiday. If you no longer want the item, please kindly send us a message and we will provide you with the address to return the item. Please note the item must be in its original condition and unopened due to security and safety reasons. CRAFTSMAN V20 RP 20-volt Max 4-1/2-in Brushless Cordless Circular saw Battery N. Front Left & Right Wheel Hub Bearing Assembly for Honda Accord 930455 2005-2 NEW. White Mirror Left Side Heated 876104Z005 for Hyundai Santa Fe Sport 2.0L 2.4 NEW. Engine Motor Mounts & Transmission Mount for Jeep Patriot (MK) Compass L4 20 NEW. DEWALT 14 -Piece Assorted x Black and gold coated HSS Jobber length Twist Drill. DEWALT TOUGH GRIP Screwdriver Bit Set 110 -Piece. Kobalt 24-volt 1/2-in Keyless Brushless Cordless Drill 1 -Batteries Included. Bosch 5/8-in Keyed Drill . DEWALT ELITE SERIES 6-1/2-in 40 -Tooth Fine Finish Tungsten carbide-tipped steel.

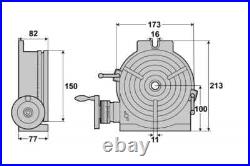

6 Rotary Table Horizontal Vertical for Milling Machine HV- 6 (3 Slot)

6 PRECISION ROTARY TABLE (HV6) – 3 SLOT. HV6 (Horizontal / Vertical). 16mm 5/8 approx. 80mm from Base to Top surface of Chuck. Graduated 360 degree around its circumference and driven by precision gear with 1:90 reduction ratio. One turn by handle moves table 4 degrees. Family-run business engaged in the manufacturing & supplying of Engineering Tools & Industrial Supplies for the last 40 years. Comprising of a dedicated & skilled team of engineers with an aim of supplying our clients with products of the highest industrial standards at the most affordable pricing.

Milling Machine Rotary Table, Versatile Horizontal & Vertical Design, Precision

100% Satisfaction Satisfaction Guaranteed. Milling Machine Rotary Table, Versatile Horizontal & Vertical Design, Precision Crafted, 4 In. Drill Attachment Product Type. Power Tool Accessory Type. 4.7 inches x 6.3 inches x 5.8 inches. Weight: 11.7 lb. Designed for precise positioning, rotation, indexing and clamping. Made of high-quality cast iron to ensure durability. Versatile horizontal and vertical installation. Rotary Table for Milling Machine. / 100 mm diameter rotary table is the perfect companion for small milling machines or specialized machinery and is designed for intricate and complex dividing cuts. Embrace the efficiency and versatility of our 4in. Rotary table and take your milling projects to the next level of accuracy. We offer the best prices around on high quality products. Our E-store includes media such as books, movies, music and games while offering electronics, toys, sporting apparel, clothing, tools, general home, garden items and more. We are always working hard to ensure your package arrives as soon as possible. We do not accept P. Please provide a physical address. We try over very best to make sure every customer is completely satisfied. If there’s a problem, message us! We’re happy to help.

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Pr

VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools4-Inch Rotary Table for Milling Machine3-Jaw ChuckClear ScaleHorizontal & Vertical UseSuperior HardnessDual Handle DesignRotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ?? 3 mm, Rotary Table Handwheel Scale Value: 6′, Worm Gear Ratio: 1:36, Center Height for Vertical Mounting Chuck: 2 in / 50 mm, Item Model Number: HV-4-KP, With or Without Vernier Scale: No, Chuck Diameter:?? 3.1 in / 80 mm, Table Diameter: 4 in / 100 mm, ?? 2 mm, Product Dimensions: 6.3 x 5.8 x 4.7 in / 160?? 120 mm, Net Weight: 11.7 lbs / 5.3 kg? .. Best choice of motor parts. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools. VEVOR Rotary Table for Milling Machines, 4”/ 100 mm, Horizontal Vertical Model Precision Milling Rotary Table, with 3.1”/80 mm 3-Jaw Chuck M10 T-Bolts Nuts, for Milling Engineering Indexing Tools 4-Inch Rotary Table for Milling Machine 3-Jaw Chuck Clear Scale Horizontal & Vertical Use Superior Hardness Dual Handle Design Rotary Table Handwheel Scale Number: 100, Top Height for Horizontal Mounting Chuck: 4.7 in / 120 mm, ?? 120 mm, Net Weight: 11.7 lbs / 5.3 kg?? Exceptional Durability, Built to Last: Step up your milling game with our exceptionally durable rotary table crafted from HT250 cast iron for maximum wear resistance and a high-hardness surface that resists scratches and corrosion, ensuring an extended lifespan. Even under heavy loads, high pressure, and rapid rotation, our rotary table maintains its integrity and durability. Choose our HT250 cast iron rotary table for a high-quality performance in your milling operations. Horizontal & Vertical Installation: When mounted horizontally, the chuck top height is 4.7” / 120 mm?? 3 mm, and when mounted vertically, the chuck center height is 2” / 50 mm. Our rotary table fits industrial and home-use milling machines as long as your milling machine tool height is higher than vertical/horizontal installation heights. Additionally, the table’s bottom features positioning slots for easy and secure attachment to your milling machine. High Precision at Your Fingertips: The milling machine rotary table is operated by a handwheel, complete with crystal-clear scales on both the wheel and the table for precise measurements. The handwheel scale number is 100, while the table itself is marked with 360 degrees. With a worm gear ratio of 1:36, a single rotation of the handwheel results in a 10-degree turn of the table, aligning perfectly with intuitive operation and allowing for precise control over even the slightest rotation. Secure Small Workpieces with Ease: Our rotary table comes with a 3-jaw chuck, and the serrated jaw ensures a firm grip on even the small workpieces. 3.1” / 80 mm. The internal jaw can be used for internal & external clamping. External Clamping Range: 0.08”-0.9” / 2-22 mm, Internal Clamping Range: 1.0”-2.8” / 25-70 mm. It includes an external jaw and external clamping range of 0.9”-2.5” / 22-63 mm. Enjoy the precise and secure machining of small components! If an unit is received defective, of course we take it back or replace it. If the unit is received as expected, we must charge for our expenses if you want to send it back. Thank you for visiting my store! Our warehouses are located in many regions around the United States. Prioritize the best quality logistics solutions to transport packages. At the same time. Have any after-sales problems.