table

Bridgeport Milling Machine 12 Rotary Table Tailstock H/V Vertical Mount Bracket

The Bridgeport Milling Machine 12 Rotary Table Tailstock H/V Vertical Mount Bracket is a high-quality, manual operation rotary table designed for milling machines. Made in the United States by Bridgeport, this product features a horizontal/vertical setting position, making it versatile for various milling applications. With a tilting and cross-slide feature, this rotary table is reliable for precision machining tasks. Additionally, it includes a California Prop 65 Warning for safety awareness. Includeding mounting base for vert/ horizontal mount.

Rotary Table horizontal/vertical manually operated Hobbyist & professional (DDP)

Gear Ratio – 36:1, which basically means that the 1 rotation of the handle shall rotate the table by 10 degrees. Table scale is calibrated in 5 degree increement. Can be used both in horizontal & vertical position.

4 Inch (100 mm)little Machine Shop 2420 Rotary Table Withdigital Read for Milling

The 4 Inch (100 mm) Little Machine Shop 2420 Rotary Table with digital read is a versatile tool for milling tasks, offering the capability to work in horizontal settings. This rotary table allows for precise and accurate machining by providing a digital read for improved control and consistency. Perfect for CNC milling and other metalworking applications, this workholding rotary table from Little Machine Shop is a valuable addition to any workshop or manufacturing facility. New in original packaging. Still has protective oil.

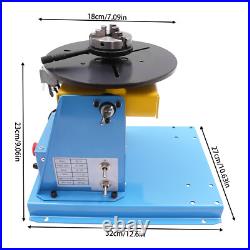

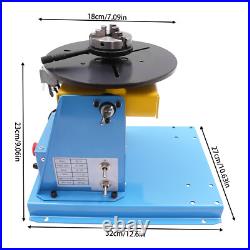

10kg(Horizontal)/5kg(Vertical) Modern Rotary Welding Positioner Turntable Table

Our welding positioner is made of high-quality steel through blackening and spray molding processes, which is sturdy and durable. It is equipped with a 3-jaw chuck with a diameter of 2.56in to hold the welding element securely for your convenience. In addition, the low-speed operation and 0-90° tilt angle make it easy for you to weld more difficult components. It is also equipped with a foot pedal that controls the start and stop of the machine, so you can concentrate on welding with ease. It is a great assistant to help you finish your welding. It is made of high-quality steel through the. Blackening and spray molding processes. To high temperatures and can ensure a long service life. It is equipped with a 2.56in three-jaw chuck with a clamping range of 0.08-2.28in and a support range of 0.87-1.97in, which effectively prevents movement and dropping of weldments, thus significantly improving welding accuracy. It features a 20W DC drive motor that runs at low speeds with 1-12 rpm. Speed regulation for stable operation. In addition, it has a load capacity of up to 11.02lbs (vertical) or 22.05lbs (horizontal) and forward and reverse functions, providing excellent stability to support efficient and precise welding. It can be tilted from 0-90° and securely fastened at the desired angle with butterfly bolts. The clear operator’s station makes it easy to adjust the speed, connect the power supply, and more. 2 chuck keys make adjusting the tightness of the chuck jaws a breeze. The product is equipped with conductive carbon brushes that can effectively avoid the risk of electrical leakage, so you can use it with peace of mind. With it, you have a more professional workbench for welding work. It can be fixed on the workbench or specific tooling for manual welding or paired with welding equipment for automatic welding. The simple structure, complete accessories, and detailed English manual allow you to complete the installation and start using it in a short time. Thanks to its smooth surface and simple structure, you can wipe the dirt from this machine with a rag(not included). With its good performance and high practicability, it would be an ideal gift for your family, friends, and others who enjoy welding. To prevent damage to the product due to bumps in transit, we place sponges to protect the product as much as possible. It controls the starting and stopping of the machine. It can be used in emergencies to suspend the machine’s operation for your subsequent repairs. It will light up when the product is plugged in and in working condition. The square base and holes in the bottom stabilize the product nicely. In addition, the hole in the bottom can also be used to place a gun holder for holding the torch (not included). The 4.92ft long power cord reduces usage limitations. It is mainly used for rotating and turning round and annular workpieces, so that the workpiece weld is placed in the optimum position for welding, such as horizontal, boat-shaped, etc. It can also be used to fix chucks or specific tools on the table to clamp the workpiece for manual welding, and can also be used to fix the workpiece on the table for cutting, grinding, assembling, testing, etc. It is especially suited for welding flanges, tubes, rounds and other parts up to 22.05 lbs. Process: Blackening, Spray Molding. Motor Type: DC Drive Motor. Power Source: Corded Electric. Flip Method: Manual Flip. Input Voltage: AC 110V. Motor Voltage: DC 24V. Horizontal Load-bearing: 10kg/22.05lbs. Vertical Load-bearing: 5kg/11.02lbs. Three-jaw Chuck Diameter: 65mm/2.56in. Clamping Range: 2-58mm/0.08-2.28in. Support Range: 22-50mm/0.87-1.97in. Power Cord Length: 1.5m/4.92ft. Gross Weight: 11kg/24.25lbs. Product Size: 322723cm/12.610.69.1in. Eter: 20.5cm/8.07in. Package Size: 363431cm/14.213.412.2in. Please strictly follow the manual for installation and use, and pay attention to the safety matters inside. To prevent electrical safety hazards, we recommend that customers use this tool with an electrician’s license or welding experience. Please note that this product cannot be used to weld plastic products. Please allow the slight color difference caused by the shooting light and 1-3cm error due to manual measurement, and make sure you do not mind before you order. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.

Palmgren 9632806 Horizontal/Vertical rotary table, 8

Palmgren 9632806 – Horizontal/Vertical rotary table, 8 – a CH Hanson Company. Palmgren 9632806 – Horizontal/Vertical rotary table, 8. WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer.

High Precision Horizontal Vertical Rotary Table Working Table Tilting 360°

Horizontal Vertical Rotary Table Working Table Tilting 360°.

Palmgren 9634105 Horizontal/Vertical rotary table, 10

Palmgren 9634105 – Horizontal/Vertical rotary table, 10 – a CH Hanson Company. Palmgren 9634105 – Horizontal/Vertical rotary table, 10. WARNING: This product can expose you to chemicals including lead, which is known to the State of California to cause cancer.

Modern Rotary Welding Positioner Turntable Table 10kg(Horizontal)/5kg(Vertical)

Package Included 1Welding Positioner 1Foot Pedal 1Power Cord 1English Manual 2Chuck Keys. Have a nice day. Our welding positioner is made of high-quality steel through blackening and spray molding processes, which is sturdy and durable. It is equipped with a 3-jaw chuck with a diameter of 2.56in to hold the welding element securely for your convenience. In addition, the low-speed operation and 0-90° tilt angle make it easy for you to weld more difficult components. It is also equipped with a foot pedal that controls the start and stop of the machine, so you can concentrate on welding with ease. It is a great assistant to help you finish your welding. It is made of high-quality steel through the. Blackening and spray molding processes. To high temperatures and can ensure a long service life. It is equipped with a 2.56in three-jaw chuck with a clamping range of 0.08-2.28in and a support range of 0.87-1.97in, which effectively prevents movement and dropping of weldments, thus significantly improving welding accuracy. It features a 20W DC drive motor that runs at low speeds with 1-12 rpm. Speed regulation for stable operation. In addition, it has a load capacity of up to 11.02lbs (vertical) or 22.05lbs (horizontal) and forward and reverse functions, providing excellent stability to support efficient and precise welding. It can be tilted from 0-90° and securely fastened at the desired angle with butterfly bolts. The clear operator’s station makes it easy to adjust the speed, connect the power supply, and more. 2 chuck keys make adjusting the tightness of the chuck jaws a breeze. The product is equipped with conductive carbon brushes that can effectively avoid the risk of electrical leakage, so you can use it with peace of mind. With it, you have a more professional workbench for welding work. It can be fixed on the workbench or specific tooling for manual welding or paired with welding equipment for automatic welding. The simple structure, complete accessories, and detailed English manual allow you to complete the installation and start using it in a short time. Thanks to its smooth surface and simple structure, you can wipe the dirt from this machine with a rag(not included). With its good performance and high practicability, it would be an ideal gift for your family, friends, and others who enjoy welding. To prevent damage to the product due to bumps in transit, we place sponges to protect the product as much as possible. It controls the starting and stopping of the machine. It can be used in emergencies to suspend the machine’s operation for your subsequent repairs. It will light up when the product is plugged in and in working condition. The square base and holes in the bottom stabilize the product nicely. In addition, the hole in the bottom can also be used to place a gun holder for holding the torch (not included). The 4.92ft long power cord reduces usage limitations. It is mainly used for rotating and turning round and annular workpieces, so that the workpiece weld is placed in the optimum position for welding, such as horizontal, boat-shaped, etc. It can also be used to fix chucks or specific tools on the table to clamp the workpiece for manual welding, and can also be used to fix the workpiece on the table for cutting, grinding, assembling, testing, etc. It is especially suited for welding flanges, tubes, rounds and other parts up to 22.05 lbs. Process: Blackening, Spray Molding. Motor Type: DC Drive Motor. Power Source: Corded Electric. Flip Method: Manual Flip. Input Voltage: AC 110V. Motor Voltage: DC 24V. Horizontal Load-bearing: 10kg/22.05lbs. Vertical Load-bearing: 5kg/11.02lbs. Three-jaw Chuck Diameter: 65mm/2.56in. Clamping Range: 2-58mm/0.08-2.28in. Support Range: 22-50mm/0.87-1.97in. Power Cord Length: 1.5m/4.92ft. Gross Weight: 11kg/24.25lbs. Product Size: 322723cm/12.610.69.1in. Eter: 20.5cm/8.07in. Package Size: 363431cm/14.213.412.2in. Please strictly follow the manual for installation and use, and pay attention to the safety matters inside. To prevent electrical safety hazards, we recommend that customers use this tool with an electrician’s license or welding experience. Please note that this product cannot be used to weld plastic products. Please allow the slight color difference caused by the shooting light and 1-3cm error due to manual measurement, and make sure you do not mind before you order. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.

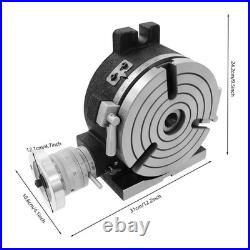

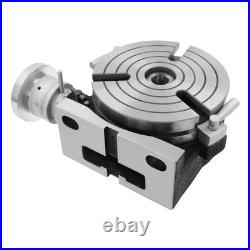

3-slot Rotary Table Horizontal Vertical Rotable Tool Holding for Milling Machine

Specifications Material: FC30 Cast Iron Color: Black, Silver Mounting Required: Yes Number of T-Slot: 3 Worm Gear Transmission Ratio: 1:90 Worm Gear Module: 1.5mm/0.06inch Max. Load Capacity (Horizontal): 100kg/220 lbs Max. Load Capacity (Vertical): 50kg/110 lbs Indexing Accuracy: 0.05° Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1° Large Wheel Scale Range: 360° Gross Weight: 12.6kg/27.78 lbs Net Weight: 12.06kg/26.59 lbs Handwheel Diameter: 12.1cm/4.7inch Product Size (Vertical): 3110.624.2cm/12.24.19.5inch Package Size: 31.52616cm/12.410.246.3inch Package Included 1 3-slot Rotary Table Other Accessories for Installation. 3-slot Rotary Table Horizontal Vertical Rotable Tool Holding for Milling Machine. It is compatible with milling machines to perform various tasks, such as indexed drilling, milling, circular cutting, boring, and more. Material: FC30 Cast Iron. Number of T-Slot: 3. Worm Gear Transmission Ratio: 1:90. Worm Gear Module: 1.5mm/0.06inch. Load Capacity (Horizontal): 100kg/220 lbs. Load Capacity (Vertical): 50kg/110 lbs. Indexing Accuracy: 0.05°. Graduated Ring of the Handwheel Scale: 4° (A Whole Circle)/30 Small Scales Equal 1°. Large Wheel Scale Range: 360°. Gross Weight: 12.6kg/27.78 lbs. Net Weight: 12.06kg/26.59 lbs. Handwheel Diameter: 12.1cm/4.7inch. : 3110.624.2cm/12.24.19.5inch. Package Size: 31.52616cm/12.410.246.3inch. Other Accessories for Installation. Crafted from FC30 cast iron, it exhibits superior wear endurance and structural solidity, establishing a reliable foundation for the product’s extended service life. Featuring a worm gear ratio of 1:90 and a module of 0.06 inches, it delivers smooth, powerful transmission. With an indexing accuracy of 0.05°, it meets the stringent precision demands of machining positioning. What’s more, the easy-to-read clear graduations bring great convenience for use. It supports a maximum load of 220 lbs in horizontal mode and 110 lbs in vertical mode. This flexible load capacity adapts to diverse processing needs, accommodating workpieces of varying weights with ease. It features a precision handwheel where 30 small scales equal 1°, and one full handwheel rotation corresponds to 4°. The larger wheel provides a 360° scale range, supporting detailed and accurate angular positioning during machining. Fitted with an innovative spindle locking mechanism, it delivers a stronger clamping force than conventional double-sided pressure plate designs. This ensures exceptional stability during use processes, directly boosting machining precision and safety. Please carefully check if the size is suitable before placing an order. Please use the product within its weight capacity to avoid damage. Please allow for slight color differences caused by the shooting light and a 1-3cm error due to manual measurement, and make sure you do not mind before ordering. Feedback is very important to us. It is impossible to address issues if we do not know about them! Faction is our ultimate goal. We work hard to earn your trust and future business. A If you receive a defective item, you may return it or ask for a discount. Due to time zones, our reply to your questions may not be immediately. If it’s non-workdays, please kindly be patient and wait till Monday.